Field applications and lessons learned: Gas-fuelled microturbines in the brick and tile industry

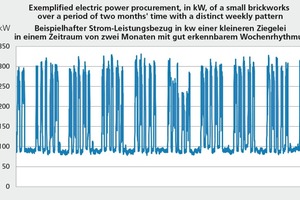

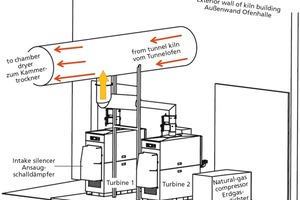

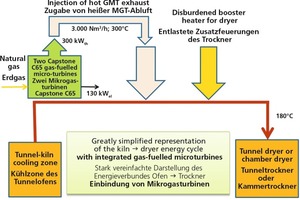

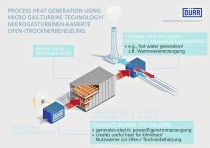

Combined heat and power generation, or CHP, with its high overall efficiency, is both ecologically beneficial and economically attractive. The brick and tile industry, with its continuous demand for electricity and heat, has recognized the CHP potential. Due, however, to the manner of heat generation involved, motor-based solutions are not widely disseminated. The technological specifics of gas-fuelled microturbines serving as CHP units, especially with regard to the direct utilization of the exhaust heat content, are helping them gain access to new areas of application in the brick and tile industry.

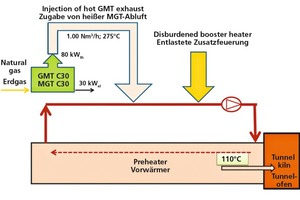

All across the sector, the main focus in this respect is on the supply of heat to dryers and preheaters as a means of disburdening in-service natural gas burners. The combination of long runtimes and the cost spread between gas and electricity as sources of energy yields short payback times, despite the latest changes in the boundary conditions governing captive power generation.

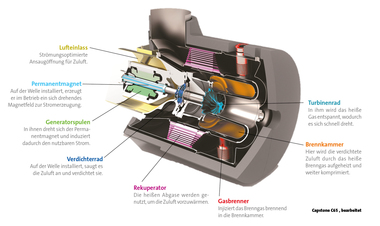

1 The technology of gas-fuelled microturbines

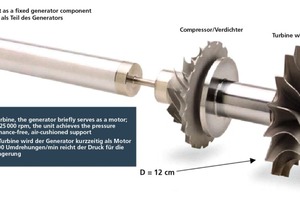

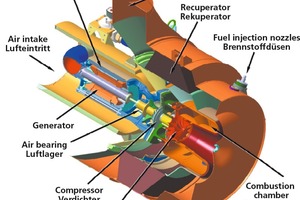

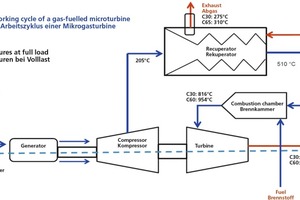

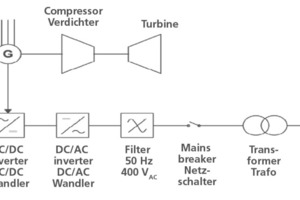

A gas-fuelled microturbine (GMT) is a small, fast-running gas turbine with an electric power rating of approx. 250 kW. Such units consist of a single-shaft turbine with a...