Reduction of the thermal conductivity

of brick bodies through fast firing

BMWi through the German Federation of Industrial Research Associations “Otto von Guericke” Regd (AiF) Implemented by

Brick and Tile Research Institute Essen Regd (IZF)Project managerDipl.-Ing. Michael Ruppik

1 Introduction

2 Objective

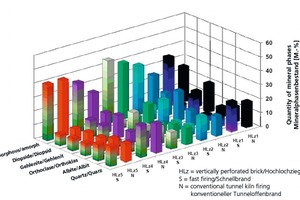

3 Results and conclusions

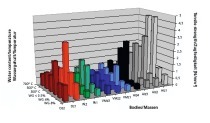

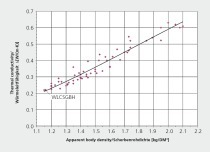

The thermal insulation of the bricks fired in significantly shorter times tends to be higher. This is indicated by comparatively lower heat conductivities, which can be verified unanimously for all mixtures tested here. On the basis of the heat conductivities determined through individual brick measurement on conventionally fired bricks, the increase of the thermal insulation amounts to 4 to 8%, in individual cases even 12%.

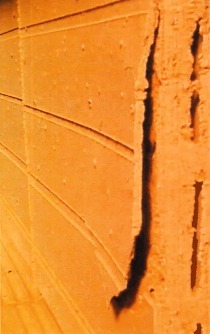

In fast firing, through the development of reaction gases, reducing atmospheres in the green brick are evoked verifiably in partial areas of the preheating section, which accelerate the sintering process. These processes determine the physical properties of the body, which, in comparison to oxidizing firing, can already be achieved at low temperatures. At least, through the acceleration of the reactions under reducing conditions, the only short dwell times in the temperature range of the sintering process during fast firing are compensated, in comparison to the longer firing times of a conventional firing process. This is one of the causes for the fact that the compressive strengths of the bricks deviate only negligibly from those of the conventionally fired bricks. In individual cases even higher compressive strengths are achieved.

When implementing the determined relations between the type of pore and void formers and the heat conductivity as well as the effect of fast firing on the thermal insulation of the bricks, the following must be taken into account: The heat transport responsible for the heat conductivity through the vertically perforated brick takes place mainly via three transport mechanisms. These are: The heat conduction through the body structure forming the brick skeleton, the heat conduction through the air in the perforation chambers and the heat radiation from web to web through the perforation chambers. The effects of these mechanisms are, in terms of magnitude, approximately equivalent, so that the optimization of the heat conductivity of the body by measures relating to the raw materials and the firing technology can only exert an influence of approximately one third on the heat conductivity of the bricks.

According to expectations, the thermal insulation of the bricks, which was improved within the scope of this project by means of fast firing, is not to be described as unusually high. However it creates security in the fulfilment of the requirements for thermal insulation properties of vertically perforated bricks. The combined use of suitable organic pore-forming agents and inorganic lightweight materials as well as a firing process adjusted to the raw material mixture create the prerequisites for the production of bricks with extremely low heat conductivities and sufficiently high strengths.

For a handling fee, the 88 page long final report is available from the Research Alliance of the Brick and Tile Industry Regd in Berlin.