Eisenmann VarioClone allows robots to be programmed more accurately and more effectively

With the methods commonly used today to program industrial robots, a distinction is made between offline simulation on a personal computer and online programming directly at the robot controller. Offline simulation yields the advantage of allowing robot programs to be created in a virtual world without directly having to access the robots in production. This eliminates the expensive stoppages necessary for time-consuming online programming directly on the robot.

Considered in terms of tolerance, every real robot is unique. In other words, the real robot always differs from the idealized robot model used in the simulation. For this reason, it was hitherto not possible to transfer new or optimized programs created through offline simulation directly to the real robot, with the result that the robot programs had to be laboriously modified with the aid of online teach-in processes or costly and time-consuming measurements.

The automotive industry in particular uses parallel production lines in order to achieve high throughput rates and minimize the impact of a robot failure on production as a whole. This fact has given rise to demands for straightforward transferability of robot programs from one production line to another. So far, however, this can only be done to a limited extent, once again due to specific tolerances and fault effects of the individual robots.

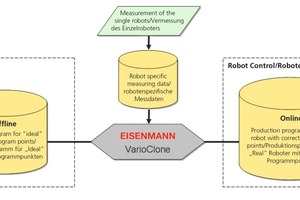

Principle of operation

The data obtained from measurement of the robot concerned are loaded into the VarioClone system and used to design a model. This individual robot model compensates the tolerances existing in the real robot. In this way, the robot programs created in a virtual world are converted via VarioClone on the basis of individual robot models and then transferred to the real robot. VarioClone consequently links the virtual world with the real world and can compensate up to 89% of the outlined fault effects.

When a robot is now to be programmed for the same tasks as its counterpart in a parallel production line, its robot program can be transferred with the aid of VarioClone. In this cloning process, the program to be copied is converted into a master program with the data saved in VarioClone for the first robot. The master program is then adapted to the individual model data of the robot to be programmed and transferred to the production line.