Experiences with Emisshield® High Emissivity Coatings in tunnel and roller kilns

Many companies in the energy intensive brick & tile industry are confronted with rising energy prices and the increasing pressure to reduce CO2 emissions. Many improvement projects have been launched in the past years to improve operations costs to oppose fuel increases. One quick, save and sustainable opportunity has been provided by CRESS B.V. with its Emisshield® high emissivity coatings with NASA origin. This Space-Certified technology uses thin ceramic materials which can be applied to several kind of refractories, ceramic fiber and metals. Average savings are around 5%, some projects even show reductions on energy costs up to 10%, all while reducing the carbon footprint.

Copyright: CRESS B.V.

Copyright: CRESS B.V.

How does Emisshield® work?

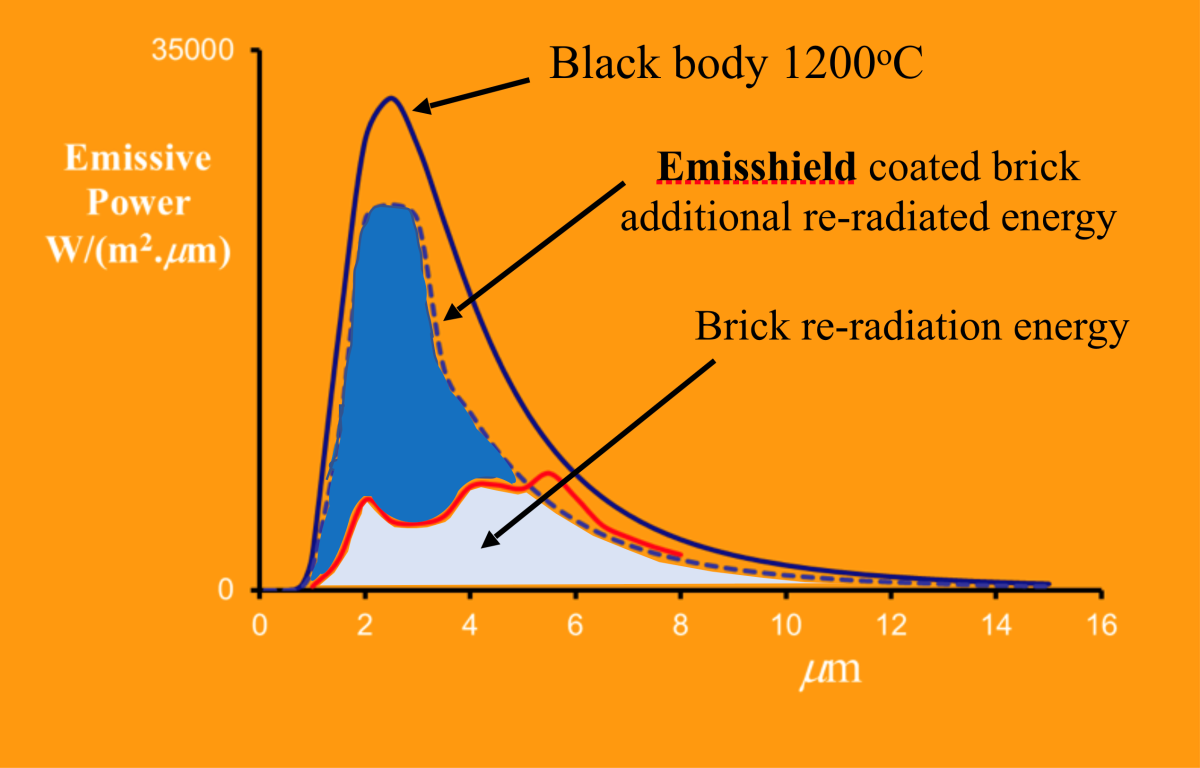

Emisshield® coatings can handle temperatures as high as 1700°C with an excellent adhesion to the surface. The ability to increase the radiant heat transfer to the colder kiln load by increasing the emissivity factor ɛ of the furnace lining from 0,4 up to 0,9 is a key property to achieve energy savings. In contrary to reflective coatings which reflect radiation at same wavelengths (a part of this reflected energy is absorbed by flue gases and lost through exhaust) high emissivity coatings absorb and re-emit radiation at different wavelengths. This ensures more radiant energy reaching the production load whilst providing more uniform heating.

Additional re-radiation capability (blue area) in the IR wavelengths

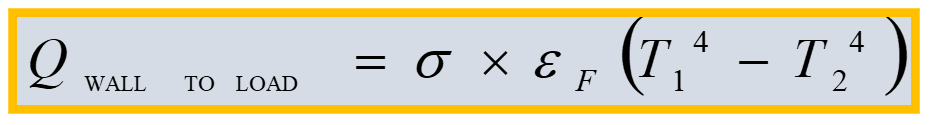

The following equation shows the impact of the emissivity factor ɛ, the temperature of the furnace wall (coating) T1 and the temperature of the kiln load T2 which are raised to the 4th power:

Where:

Q = re-radiated energy absorbed by the kiln load

ɛF = emissivity of the coating

σ = Stefan-Boltzmann constant

T1 = wall temperature

T2 = load temperature

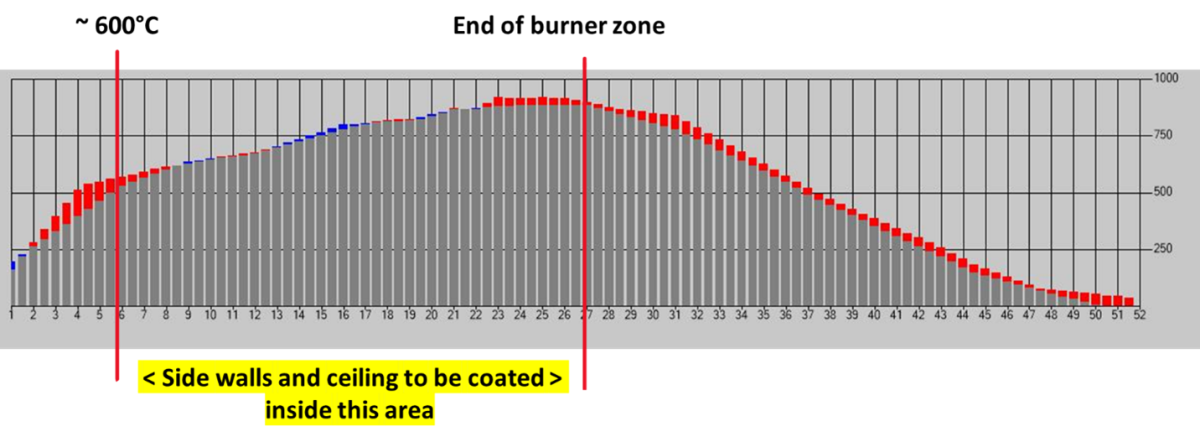

It is important to understand that Emisshield® absorbs and re-radiates the most energy when the temperature difference between the walls (coating) and the load is the greatest. Therefor continuous operating kilns are coated only inside the area shown hereafter

Emisshield references

Copyright: CRESS B.V.

Copyright: CRESS B.V.

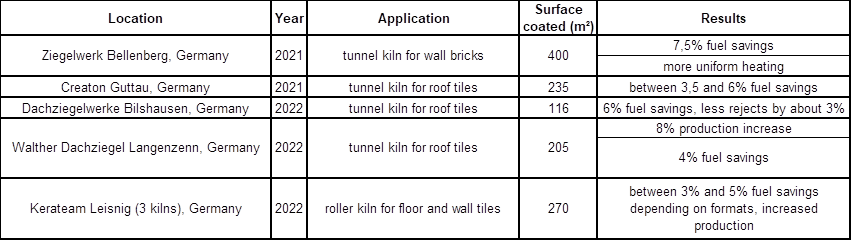

Based on the successful tests of the coating in 2020 at the institute for brick and tile research in Essen, Germany, the coatings got attention from several customers in Europe. Due to the fact that the return of investment usually is < 1 year and calculating with the Emisshield® Product Life Expectancy of 5 to 7 years, about 30 roller and tunnel kilns have been coated throughout Europe within the last 2 years producing wall bricks, roof-, wall and floor tiles, or flower pots.

Selected references from Germany

Selected references from Germany

Copyright: CRESS B.V.

Explore our website for a full look at our technology.

We look forward to hearing from you!

Herbert Gruenbichler

Salesmanager Europe

Tel: +43 676 5798795