Vandersanden Opens Unique Pirrouet Production Facility in Lanklaar, Belgium, with New Brick Press from Rekers GmbH

With over 800 employees across 14 locations in Europe and the United Kingdom, Vandersanden ranks among the largest and leading family-owned brick manufacturing companies in Europe. Its product portfolio includes amongst others facing bricks, brick slips, paving bricks, and recently, the CO2-negative facing bricks Pirrouet. With an investment of €32.5 million and an EU research grant of €2.2 million, the Vandersanden Group established a new plant near the tri-border area close to Aachen with 26 employees on an 8,000 m² site dedicated to the production of Pirrouet facing bricks. The heart of this pilot facility is the innovative RSP-500 brick press from the medium-sized family business Rekers GmbH Maschinen- und Anlagenbau, located in Spelle. This cutting-edge brick press enables a current production capacity of 20 million facing bricks annually, which can potentially be doubled to 40 million with the planned addition of a second press. This brick press opens new production possibilities for forward-looking products, while saving energy and resources compared to conventional machinery. The plant was officially inaugurated in September 2024, marking another milestone in Vandersanden’s sustainability concept. But that‘s not all, Vandersanden has also been awarded the German Sustainability Award (DNP) in the area of climate change with its CO2-negative Pirrouet facing bricks.

Focus on Sustainability

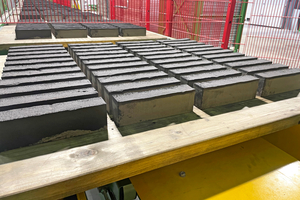

The new production facility will exclusively produce climate-friendly products under the Pirrouet label. These sustainable facing bricks are set as the standard, meeting specific requirements, including 80% recycled material and 60 kg of CO2 binding per ton of facing brick.

In addition to the products, employee well-being is also a priority. The modern production facility provides excellent working conditions with ample natural light and high operational safety. The plant is designed to minimize employee exposure to noise and dust and features a maintenance-friendly layout for ergonomic working conditions. This includes an intelligently designed brick press, reducing movements in the production process, minimizing wear parts, and facilitating easy maintenance and cleaning access for operators.

The facility represents a forward-looking investment, with energy efficiency and emission reduction as its key focus. Water recycling systems ensure that all processed water is treated and reintroduced into production, while rejected products are also recycled back into the production process.

During the curing process of the facing bricks, CO2 is added to create a chemical bond with calcium-containing materials, binding CO2 in this product. With an annual production capacity of 20 million facing bricks and a CO2 absorption capacity of 60 kg per ton, the production facility can capture 2,280 tons of CO2 from the atmosphere each year.

This pilot plant emerged from a preceding test phase, during which a small brick press produced prototype facing bricks and developed the optimal CO2 absorption solution. Following this successful test phase, the choice of machinery and plant manufacturer for this brick press and the entire production facility fell on Rekers GmbH, not only due to their commitment to implementing holistic, innovative solutions with high-quality standards but also because of their proactive stance on sustainability and shared values.

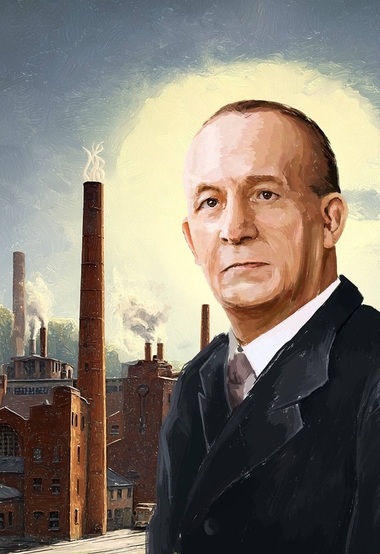

New Rekers RSP-500 Brick Press for New Corporate Goals

In choosing the right machine for their goals, Vandersanden opted for a groundbreaking new brick press from Rekers. The up to now unique brick press type RSP-500, designed by CEO and owner Norbert Foppe, was a decisive factor. The appearance of the brick press was inspired by Rekers‘ also new and innovative block and paver machine RS4.

Although the manufacturing process and operating principle are fundamentally different, the brick press can be compared to a sand-lime brick press to better understand its innovative aspects.

Unlike a sand-lime brick press, where the fresh product is transferred by a grab onto a curing car, here, it is demolded directly in the brick press and transported on production boards to the curing chamber, improving quality standards and product handling.

These are just a few reasons why Rekers was chosen as the supplier of the brick press.

Pirrouet Facing Brick Coloring

Rekers has been a true pioneer in the automated coloring of product surfaces since patenting the innovative Rekers Colour Blending System in 2006. This system can precisely dose up to six different color blends of the brick press. It enables the production of individual, unique, and naturally textured surfaces with attractive color variations. The mixed color batch is fed from the face mixer to the Colour Blending System via a flexible flying bucket system, which can be customized from the mixer to the distribution hopper. The 500-liter flying bucket with bottom discharge deposits the fresh batch into the hopper, with precise dosing enabled by individual weighing cells on each of the six hoppers, allowing exact amounts to be placed on the conveyor belt for layered color application. From the conveyor, the colors are transferred to the distribution belt and placed as desired in the brick press’s face mix hopper, creating unique color effects.

This multi-color surface design achieves natural-looking color patterns, which can be both reproduced and generated randomly. The patented Colour Blending System, combined with a flying bucket system, offers numerous benefits in terms of maintenance and cleaning, with easy accessibility and a maintenance-friendly design.

Sound enclosure for a pleasant working environment

One special feature of the production facility around the brick press is that, due to the low noise level, a sound enclosure room for the brick press is not required. The press is secured by protective fences, ensuring an unobstructed view of the production process.

However, the sound enclosure room for the brick press’s hydraulic station, as well as the enclosures for the operator and control cabinet rooms, are supplied by Kaschwig and were installed in close collaboration. These parts of the facility offer excellent accessibility, as the hydraulic station, control cabinet room, and Colour Blending System are all located on a shared platform at a height of 4,000 mm.

Wet side

The fresh products are conveyed cycle-by-cycle using a nearly maintenance-free walking beam conveyor with product-specific, freely adjustable speed ramps. The wet side also offers open spaces for future expansions due to innovative technology. Additionally, the wet side integrates a product dumper within the walking beam conveyor. In an automated process, this dumper is linked to product control, dumping defective batches in a container where they are crushed and reintegrated into the production process. Finally, the walking beam conveyor transfers the products to the curing area.

Loading Device

At Vandersanden, a conventional elevator does not stack each board over each other. Instead, a counterweight loading device transfers products directly from the walking beam conveyor to one of two buffer racks on the rack exchange car. The rack has 33 levels, with each level used for products up to a height of 75 mm. The loading device operates with quick and precise movements, which can be adjusted for specific product requirements. Additionally, the loading device offers significant advantages in terms of maintenance, as the belt drive eliminates chain elongation and the need to replace heavy chains with bolted angles. The rack exchange car is used to minimize wait times between the machine and the finger car.

Rekers sturdy finger car

As is typical with Rekers, the finger car is designed to be extremely robust, ensuring long service life and reliable operation. In its latest version, further steps have been taken to simplify and reduce maintenance and upkeep. The positioning of the finger car and transfer car relies on proven laser distance measurement. Signal and data transmission generally occur via Bluetooth or WiFi.

The finger car’s control system enables full automation and monitoring of the entire process up to unloading, including pre-settings for the dry side and packaging line. Based on the stored product-specific curing times and parameters, products are automatically retrieved after the designated time, additionally, the dry side as well as packaging side set to the appropriate parameters for automated operation.

Due to the CO2 addition during the curing process, it is necessary to hermetically seal the individual curing chambers, which interrupts the rail structure of the finger car’s upper car in these areas. Two drive axles allow the finger car to cross this interruption between the first rails and the rails in the curing chamber, facilitating the loading and unloading of products within each curing chamber. To make this transition smooth, two pedal axles are mounted on the upper section.

Furthermore, the finger car allows for the opening, moving, and closing of each curing chamber door, ensuring an optimal and safe curing process. Additionally, the finger car is equipped with a rotating unit, which will be used in the future to transfer the products to a finishing line in another hall after curing.

Curing Chamber Rotho Pro Carbon Cure system

Vandersanden relies on the pioneering technology of the Rotho Pro Carbon Cure system for the curing of Pirrouet bricks. This system enables the safe carbonation of the products in an atmosphere with a high CO2 concentration. This was necessary, since curing products with binders based on mineral residues from the steel industry requires a paradigm shift, as the mineral steel residue needs carbon dioxide to achieve strength. Typically, common binders like cement or adhesives harden in air, reaching strength over time; however, steel slag binders achieve this only minimally and over a very long period. Therefore, creating a high CO2 concentration environment is essential to sufficiently infuse products with carbon dioxide. By creating such an environment, the facing bricks can absorb large amounts of CO2, thus contributing significantly to CO2 sequestration. Developing a new curing technique was essential, as the established process technology from the concrete industry was not suitable. The Rotho Pro Carbon Cure system was developed and has proven effective at Vandersanden for carbonating the Pirrouet facing bricks made of residue-based binders.

The decision to commission Rotho for the CO2 curing chambers was also based on Rotho’s expertise in curing concrete products as well as in drying ceramic products like roof tiles and bricks. Knowledge from both disciplines is required to achieve optimal carbonation of Pirrouet facing bricks. This approach is based on the fact that CO2 must diffuse into the product to react with the mineral steel residue. This also requires the evaporation of some of the mixing water and the creation of capillaries to transport CO2 into the product’s interior. Considering that high CO2 concentrations can be harmful or fatal to humans, several quality-compliant requirements can be defined, which are essential for CO2 curing:

1. CO2 Supply: CO2 supply is the central element in carbonating Pirrouet facing bricks. Precise dosing of CO2 is crucial for a stable process, as a closed system can react with rapid pressure fluctuations due to too much or too little CO2, potentially triggering safety systems and creating an unmanageable process. A CO2 control system was developed to automatically supply the necessary CO2 quantities to the process.

2. Ventilation System: Ventilation technology is essential to ensure that all products are sufficiently supplied with CO2. Without enough CO2, products may not achieve the necessary strength, resulting in possible failure in use. Consistent product quality requires an even distribution of CO2 across all products in the chambers. This is achieved by the installation of special nozzle walls that ensure uniform treatment of all Pirrouet facing bricks throughout the chamber’s depth and height.

3. Closed Carbonation Process: Normally, convective drying occurs in an open process, with warm, dry air introduced and colder, humid air discharged to the environment. However, with high CO2 concentrations, a significant portion of CO2 would be vented with the moisture, reducing CO2 available for carbonation and releasing more CO2 back into the atmosphere. To prevent these effects, carbonation must occur in a closed process. The climate chamber can be time-controlled via corresponding curing programmes stored in the process control.

4. Construction and Door Sealing: National workplace standards for permissible CO2 concentrations require high sealing standards for the chambers and ventilation systems. Rotho’s Pro Carbon Cure system uses the self-developed, patented Quatro structure, a self-supporting sheet metal wall system that achieves the highest seal class per DIN EN 1507. A significant advantage is that connection elements, like pipes, flanges, and measuring ports, are welded firmly and tightly into the walls. Such tightness is simply unachievable with standard sandwich panels.

5. Safety Devices: CO2’s harmful effects on human health necessitated a preliminary HAZOP analysis. This analysis systematically examined both hazards and operational capability to ensure high safety for personnel, equipment, the environment and functionality. Based on this risk analysis, Rotho developed safety features like a leak monitoring system for continuous sealing checks, multi-stage pressure monitoring, and SIL-compliant safety valves, among others. Ensuring a safe facility was a primary focus for all project participants.

6. Control and Regulation: Coordinating all upstream and downstream systems, such as CO2 supply, CO2 monitoring in the curing hall, and ventilation systems, is crucial to the successful start-up of Pro Carbon Cure chambers. Rotho’s control system acts as a central management system to process all these signals into a safe and reliable operation.

Rotho is making an important contribution to storing large quantities of carbon dioxide with its Pro Carbon Cure technology for carbonating Pirrouet bricks - the first bricks with a negative carbon footprint.

Unloading Device Including rack exchange car (Buffer function)

The unloading device operates similarly to the loading device on the wet side. Additionally, the dry side is equipped with a double rack on the rack exchange car to buffer the cured products. This allows the finger car to deposit cured products while the unloading device retrieves products from the other rack. Once the first rack is emptied, the rack exchange car shifts so the unloading device can immediately unload products to the dry side. This setup is a smart and cost-effective buffering solution compared to conventional designs using additional dynamic buffers or a second (double) lowerator.

Dry Side on two levels

Another innovation is the two-level setup of the dry side. The unloading device is connected to a board conveyor, specifically a belt conveyor, which conveys the boards with cured products to another cross-belt conveyor. Along this conveyor, a product compactor detaches products from the board, improving cycle time efficiency. Using an elevator, the boards are raised to a second level at 2,500 mm. Behind the elevator, there is also a sorting area for lab bricks, allowing cured products to be taken for laboratory testing.

On the second level, a walking beam conveyor conveys the boards towards two product transfer grabs arranged in sequence. Each of these product transfer grabs taking two rows of pushed-together products and places them onto two parallel product conveyor lines, also installed at a height of 2,500 mm.

These two parallel conveyor lines provide the advantage of allowing different products to be individually directed to a finishing line. Later in the packaging process, it is possible to recombine and merge products from both conveyors, enabling a higher degree of customization and flexibility. Furthermore, the two-level design creates clear pathways for movement around the product conveyors, enabling quick access between the operator and laboratory rooms. Identical components are used for all product-handling machines on the dry side, simplifying spare parts inventory and promoting efficient maintenance and repair.

Ergonomic Product Inspection

Despite limited space in the facility due to the significant increase in delivery volumes during the project, all parties involved maintained a strong focus on providing adequate space and ergonomic platforms for effective product inspection and system monitoring.

For manual product inspection, the product conveyors allow ample room at the attached robotic packaging station. Numerous access points and generously sized maintenance platforms ensure all areas remain accessible, allowing operators to move safely and efficiently within the facility.

Flexible Robotic Packaging line

The packaging robot creates two half-packs made up of facing bricks from both product conveyors. This configuration means the brick packages consist of corner and standard bricks. The robot picks up a layer of bricks and stacks it on shipping pallets, which have been previously separated and positioned on a horizontal pack conveyor carousel by another robot. A third robot with a vacuum unit applies intermediate layers of sheets between the individual brick layers. Robotic packaging provides high flexibility and customization options for individual brick packages. Furthermore, the packaging robots are space-efficient and require minimal maintenance, with excellent accessibility via maintenance platforms and walkways.

Horizontal pack conveyor carrousel and Packaging Machines

After the product packages are created, the half-packs are transported through the packaging machines by a horizontal pack conveyor type carrousel system with multiple frequency-controlled drive segments. The half-packs undergo vertical strapping and a shrink-wrapping machine before being combined into a full pack. This complete product pack out of two half packs then passes through a second vertical strapping process. Additionally, a real-time labeling system affixes all relevant product information to the side of the package during the conveyor process. The horizontal pack conveyor carrousel was designed with an outdoor storage capacity of up to 10 packages.

System Safety

System safety meets the latest standards, incorporating an IO check, a safety matrix, and a key transfer system for cleaning and maintenance activities to ensure a power-off state in each safety zone. The safety zones are enclosed by protective fences and enhanced with light curtains and barriers in the product inspection areas.

Maintenance platforms and generously sized access gates ensure excellent accessibility to individual system components and safety zones.

Rekers Control System Including Product Tracking 4.0 - A New Approach to Data Collection and Processing

The Rekers control system for the production facility at site Lanklaar offers simple and intuitive operation of the entire plant, including a database for user management, product/component management, recipe and component control, batch logging for all mixtures, and much more. The uniform operating concept with standardized electronic, programming, and visualization systems ensures straightforward and intuitive plant operation. Data collection and processing are increasingly critical for both machine manufacturers and producers. To optimize production planning and management, the control system is integrated with Vandersanden’s ERP (Enterprice Ressource Planning) system, allowing traceability of analyzed data via labeling codes. This places Vandersanden a step ahead of other facilities in terms of traceability.

Simplified Spare Parts Management with Online Access

Vandersanden is also well-equipped for spare parts management with Rekers’ personalized online access. Online, each machine can be viewed as a 3D model, simplifying part selection. The total number of installed parts can be quickly and easily determined to facilitate spare parts inventory. The online access also provides documentation and tracks maintenance intervals for each machine component and the entire facility.

Pilot Plant Sets a Benchmark

The pilot plant centered around the brick press represents not only a future-oriented investment but also a landmark in sustainable and climate-friendly production processes for facing bricks.

Thanks to innovative process technology, it is possible to produce facing bricks that capture atmospheric CO2 while maximizing energy efficiency. Vandersanden follows a holistic sustainability approach, beginning with a power supply from its own photovoltaic and wind energy sources. This continues with the production of facing bricks that can be manufactured with significantly lower energy and absorb up to 60 kg of CO2 per ton. During production, another focus is on implementing quiet processes without heavy use of hydraulic oils. The advantages of this facility are further rounded out by its employee-friendly environment. The bright production hall includes a comprehensive safety concept, efficient layout with short paths, ergonomic working conditions, and excellent accessibility to safety zones and system components for user-friendly maintenance.

Through this successful collaboration with Rekers GmbH, Vandersanden makes a significant environmental contribution while setting its sights on its goal of becoming completely CO2-neutral by 2050.

Vandersanden selected Rekers because of the shared corporate philosophy: innovative machine technology for the highest and future-oriented product requirements combined with maintenance-friendly machine access. Rekers considers not only the machinery and the final product but also user-friendly operation and energy-saving equipment for the future. This alignment, along with quick and straightforward communication, convinced Vandersanden to partner with Rekers in bringing the innovative Pirrouet production facility to success in Lanklaar.