Heavy Clay Day

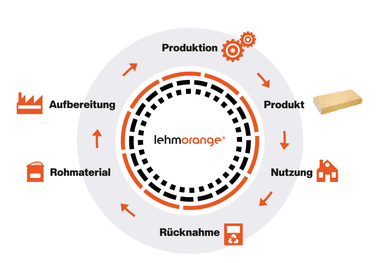

All branches of industry, including and in particular the heavy clay industry, are now facing a challenge to use resources efficiently and to provide energy efficient products and processes.

Sponsored by Zi Brick and Tile Industry International and Ceramitec, “Heavy Clay Day“ explores the subject of “energy efficiency“ from one end to the other – from the raw material clay and the manufacture of bricks and clay masonry units (via energy efficient drying and firing) to energy optimization of entire production processes and on to energy efficient buildings. Ways and means of saving energy are presented and explained.

10.00 – 10.30 Uhr

Sustainable energy efficiency optimization

Bayer Technology Services has developed a new control instrument for making production more energy-efficient and climate-friendly: the Bayer Climate Check.

With this tool it has become possible for the first time to evaluate not only the production plant itself but also all the raw materials and energy needed for production together with the logistics up to the factory gate.

The climate-relevant assessment is achieved with a new key performance indicator, the so-called “climate footprint“. The climate footprint provides decision-makers with an ecological criterion for assessing production processes and investment and technology projects in addition to the conventional profitability indicators.

With the aid of the Energy Efficiency Check, which is aligned to the Six Sigma method, suitable lists of activities are drawn up and optimization methods prioritized.

The CO2 reduction measures extend from the simple improvement of individual pump systems, through complex switch arrangements for heat flows, to innovative developments from the field of process intensification, such as new reaction methods using micro-reaction technology. Additional measures can range from better coordinated delivery chains to far-reaching optimization of work procedures such as automation or the visualization of CO2 emissions.

The methodology of the Bayer Climate Check is oriented to internationally recognized standards. To document the transparency and objectivity of the procedure, the methodology of the Bayer Climate Check has been certified by TÜV Süd, one of the world‘s leading auditing organizations in the field of climate protection. The Bayer Climate Check will also be offered to other companies as a tool for reducing CO2 emissions.

Dr. Philip Alexander Bahke,

PT-PD-Process Analysis, Bayer Technology Service GmbH,

Leverkusen

10.30 – 11.00 Uhr

Heat accumulators for intermediate storage of

combined-system heat in brick plants

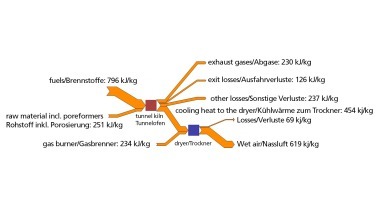

Combined-system problems due to asynchronies can be solved by temporarily storing in a heat accumulator the cooling heat that can not be directly utilized by the dryer at certain times, so that the dryer can draw from that heat when its heat requirement can not be fully satisfied with cooling air from the energy network. It would appear useful in this connection to employ a regenerative, direct-flow heat accumulator filled with clay bricks and storage medium.

Such intermediate (buffer) stores consist of counterflow regenerators of the kind used in endogenous afterfiring systems in the heavy clay sector, the difference being that combined-system heat accumulators have to accommodate and release very large quantities of heat at intervals of hours or days, so they must be accordingly large.

Nevertheless, considering the amount of energy that can be saved, the cost of investment for bridging short-term differences between the dryer‘s heat requirement and the available amount of cooling heat is quite modest. If, however, the aim is to bridge entire weekends, correspondingly large storage capacities are needed, and demonstration of cost efficiency becomes more difficult – unless an idle tunnel kiln happens to be available for use as a heat store.

Dr. Karsten Junge,

Institut für Ziegelforschung Essen e.V., Essen

11.00 – 11.30 Uhr

New options for conserving more drying energy

Combining the time-tested with modern technology, the ChoriTherm drying process is designed to conserve energy and reduce CO2 emissions.

The name of this new drying process was borrowed from ancient Greek, in which “choris“ means without and “thermasia“ (accent on the first “a“) means heat. As the name implies, this approach to drying requires no energy from fossil fuels.

Our forefathers made use of wind and “free“ heat for drying. In fact, the speaker‘s own grandfather still used such a dryer. On the other hand, we no longer have the freedom to produce as many rejects as they did back then.

Consequently, the goal was to arrive at a good combination of grandfather‘s open-air dryer and modern process technology. This contribution explains how that was achieved.

Christian Wagner, Novokeram Max Wagner GmbH, Krumbach

11.30 – 12.00 Uhr

Energy parameters as a basis for successful

energy management

This paper‘s goal is to generate more appreciation of the need for energy parameters. Energy parameters are the only sensible instrument for rendering the efficient use of energy gaugeable. Accordingly, this contribution intends to demonstrate how the “energy controlling“ process can be organized around technical and energy parameters.

Thomas Schedl, Berg Energiekontrollsysteme GmbH, Martinsried

13.00 – 13.30 Uhr

Raw material clay – the finest that nature has to offer

This paper is about the finest thing that nature has to offer – the raw material clay. And “finest“ means more than just its micro- to nano-range mineral structures – but also and mainly what can be made out of it: bricks – the world‘s finest building materials as a unique combination of tradition and innovation.

Against a backdrop of technical innovations serving to increase energy efficiency, a systematic succession of clay-base raw materials are presented by way of international case examples (Egypt, Germany, Indonesia, Romania). Due to their particular geological characteristics, the raw materials in question are singularly predestined for use in the ceramic industry. Under the heading “Modern clays“, causal connections between geological origin and certain ceramic-processing properties are demonstrated on a model basis. The presentations include an albite claystone (effect: “gloss without glazing“), a thermal-metamorphically transformed clay (effect: “prefired clay“) and a geologically dehydrated clay (effect: “dry without drying“).

Such phenomena used to be of interest to practically no one outside of hobby geologists, but it is now becoming clear that so-called “modern clays“ are attracting more and more attention. So far, only a few geological highlights have found their way, more or less by accident, into the brick and tile industry, but before long, every single “upstream service“ that nature is willing to provide will come to be regarded as more than welcome. The Institut für Ziegelforschung (IZF) has already furnished some initial systems engineering concepts for heat economy optimization at brickmaking plants. From a raw-materials viewpoint, it is high time to stop relying on coincidence and start activating some available potentials. Counter the crisis with innovations – that is a brilliant strategy!

Dr. Lutz Krakow, Dr. Krakow RohstoffConsult, Göttingen

13.30 – 14.00 Uhr

Alternative fuels – opportunities for saving energy

As conventional fuels become increasingly expensive, the urge to find and use alternatives to natural gas, petroleum and other fossil fuels is becoming more and more pressing. One question remains, however, albeit one that always calls for individual-case answers: “What do alternative fuels offer more of – opportunities or risks?“

In the manufacture of backing bricks, the use of low-cost substitute fuel in the form of admixed opening materials is basically no problem. In the firing of roof tiles, flower pots, pavers, facing bricks and clinkers, though, this is not an option. For any such fair-faced products, any deviation in fired colour, however minor, would have such serious consequences, that the use of different fuels must be ruled out, especially if the composition of the fuel in question is subject to occasional or frequent fluctuation. At first glance, then, it would appear that no advantages are to be gained from emissions trading, e.g., from resorting to renewable fuels. Another problem in that connection is that most alternative fuels are only available in the solid state, while most solid-fuel combustion systems have long-since been dismantled and replaced.

Another factor to be considered in connection with alternative fuels is their CO2 emission levels. Hence, the best substitute for fossil energy is biogenic energy – and that is the solution we are looking for. The cleanest and probably quickest way to substitute fossil fuels with regenerative fuels is to opt for animal fat, vegetable oil or biogas. Like heavy or light fuel oil, animal fat can be used in slightly modified burners, and it costs about the same as conventional fuel. Its main advantage, though, is that it counts as a biogenic, meaning that it does not factor into CO2 trading.

All the many solid-state alternative fuels and substitutes are problematic in that the equipment downstream of existing kilns – such as packed-bed filters and regenerative thermal oxidation systems – can not easily cope with the resultant dust (ash) and may be prone to malfunction. In addition, today‘s products are subject to such stringent quality criteria, that any contact with ash could have product-deteriorating effects. This applies not only to fair-faced products, but just as well to masonry bricks too, because no one nowadays would be willing to accept bricks with dust-packed perforations. In any case, such bricks would have to be “cleaned“ prior to packaging.

And so, the question of whether alternative fuels offer more opportunities or more risks still can only be approached on an individual-case basis.

Eckhard Rimpel, Institut für Ziegelforschung Essen e.V., Essen

14.00 – 14.30 Uhr

Energy efficiency with refractory systems

When it comes to firing technology, energy efficiency commands a high place value, and it can be achieved not only by installing modern equipment, but also by upgrading existing facilities. Sustainable savings on energy can be achieved by use of optimized lightweight refractory systems. Diverse implementation options are presented by way of practical examples. Substantially improved cost situations and such major environmental aspects as reduced CO2 emission certificate requirements are convincingly explained and quantified.

Márton Varga, Burton GmbH + Co. KG, Melle/Buer

15.00 – 15.30 Uhr

Brick architecture in Europe – How can we arouse

enthusiasm for building with brick?

A plea for solid construction, including abundant information about bricks in all their various applications plus photos of the most attractive academic excursion destinations of Ziegel Zentrum Süd in recent years. Against the backdrop of work accomplished at universities in southern Germany, this contribution explores the criteria of essence guiding lecturers and students of architecture and construction engineering in their decisions concerning the use of building materials. The intention is to provide insight into the myriad constructional, physicostructural and design options that are now available for modern building projects. Energy efficiency, sustainability as fundamental concepts of brick construction are illuminated as increasingly vital aspects of building design. Examples of outstanding European architecture, including many prize winners, are offered to show how building designs and shells of expressive clinker conceptions marked by out-of-the-ordinary finishes and remarkable shades of colour can arouse such enthusiasm.

Dipl.-Ing. Architect Waltraud Vogler, Ziegel Zentrum Süd, München

15.30 – 16.00 Uhr

The energy efficient brick house of the future

Europeans spend 90% of their lives in buildings. No wonder, then, that the building sector accounts for 40% of all greenhouse gases and of all energy consumed. Moreover, last winter‘s gas crisis showed just how dependent Europe is on imports of fossil fuel from countries like Russia and Iran.

This clearly defines the future way to go in the building sector. Modern structures must consume little energy, emit hardly any greenhouse gases, and, if possible, do without fossil energy resources. Of course, this all has to be of maximum quality and low cost, too.

Such ambitious goals can only be achieved through optimal harmonization of the building envelope, the heating system and the source of energy. Single-minded concentration on the building envelope leads nowhere, because modern buildings already have very low overall energy consumption rates. The heating system and, above all, the source of energy offer much higher savings potential. The presentation includes comparison calculations that show how much leverage can be attributed to alternative heating systems based on renewable sources of energy like biomass and solar energy, and the fact is demonstrated that zero emission buildings can be built with solid masonry.

Dipl-Ing. Alexander Lehmden, Wienerberger AG, Vienna, Austria

16.00 – 16.30 Uhr

Global Savings Potentials by utilizing modern Structural Ceramic Building Methods

The future challenges for politics and the global economy are tremendous: Only a modest consumption of energy will lead to a sustainable solution for the worldwide climate change. About 8% of the worldwide CO2-emissions are caused by temperature control in buildings. Unfortunately, energy-efficient ceramic building materials are used only sparingly (and mainly in German-speaking countries). The U. S., and also the emerging boom countries, such as China and India, are coming into focus as particularly interesting markets for such modern building materials. The highly thermal insulating ceramic construction materials, which have been developed mainly in German-speaking countries, are at the cutting-edge of technology with respect to their physical building properties. They have the potential to play a dominant role in attaining the energy-savings goals of the respective political administrations. Worldwide and universal usage promises enormous potential for saving energy and CO2-emissions while simultaneously improving the living comfort and quality.

Dipl.-Ing. MBA Frank Appel, Lingl Anlagenbau und Verfahrenstechnik GmbH & Co. KG, Krumbach