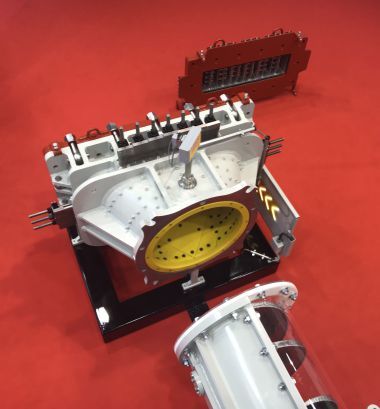

Integral Plant Maintenance: Maintenance services for boosting plant performance and productivity

For companies to run efficiently, plant and machinery have to be maintained and replaced as necessary. Maximum use has to be made of production facilities, and unplanned downtimes must be avoided. This is why proactive maintenance continues to play a key role in today’s high-performance world. With “Integral Plant Maintenance,” the Siemens Customer Services Division offers a comprehensive range of services for maintaining plant and equipment.

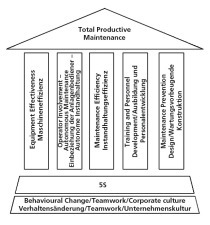

1 Goal

The goal is to reduce maintenance costs on a lasting basis, to make more effective use of the operating time of plants and equipment, to reduce lifecycle costs, and to improve the overall performance of the plant.

The Siemens Customer Services Division offers industry-specific services for maintenance worldwide, covering the spectrum from maintenance contracts and maintenance centres to solutions to manage and ensure effective and efficient maintenance for a plant or a complete operation. These services make it possible to cut maintenance costs, reduce spare parts inventories while...