Alternative waste heat recovery

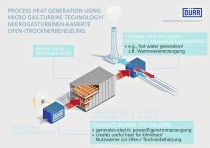

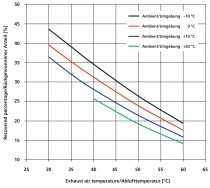

Around the world, some 50% of all process energy is expelled unused as waste heat. It is therefore extremely important that ways be found to make better use of such off-heat from production processes. In the brick and tile industry, for example, the kiln/dryer heat cycle makes poor use of such energy. However, recent research has yielded numerous new findings that can help turn waste heat back into useful energy – thereby increasing production efficiency – with the aid of new technical solutions. For instance, process heat can be recovered and either returned to the cycle or used for generating electricity by way of a gas turbine or thermoelectric module. A different option is to store waste heat for use at times when less process energy is directly available. Obviously, there is no such thing as a universal recipe for using waste heat more efficiently. Each plant requires its own individual solution. This contribution presents some new technical alternatives and offers a number of examples in which technically feasible solutions can be incorporated at brick and tile production facilities.

Dr.-Ing. Ullrich Knüpfer, IZF Essen e.V.