Digitalization as the key to efficient building

The construction industry is lagging behind when it comes to digital change – and that has consequences: While the productivity of the German economy has risen by 11% in the last ten years, and in the manufacturing and production sector it has even increased by 34 % and 27% respectively, the figure in the construction industry is just 4 %. Prof. Christian Glock, Department of Civil Engineering at the Technical University of Kaiserslautern, explains to us why digitalization can become a productivity driver for the construction industry.

C. G.: To be honest, the construction industry has been stagnating even since the 1970s. This is because promising product and process innovations are not reflected in value creation. In my view, this is mainly because so much efficiency is lost at the interfaces between design and construction that any progress gets eaten up by it. In concrete construction alone, much has happened in the last 100 years. There are new processes, new formwork techniques and completely different strengths. It is similar in steel construction and even in masonry construction – if you think how and with which bricks brick masonry used to be built in the past. Today there are sand-lime bricks in large formats and bricks with improved thermal insulation properties.

C. G.: That is right. We find countless innovations in all areas, but they do not lead to an increase in overall productivity. It rather seems as if the interface losses are getting bigger and bigger and the optimization of the overall process is increasingly out of focus. Conversely, however, this also means that in the construction industry there could be great opportunities arising from digitalization. Because the strengths of digital solutions address precisely the weaknesses of the construction industry – process and interface optimization.

C. G.: Since only a small percentage of construction projects are currently being implemented with modern digital processes, this is hardly reflected in the statistics. Compared to other industries, the construction industry still has a lot of catching up to do in terms of digitalization. However, this also results in great potential opportunities. After all, networked and solution-oriented teamwork, as required by BIM methodology, for example, optimizes processes and prevents redundancies along the entire value chain.

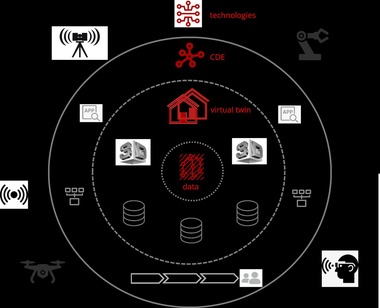

C. G.: Yes, on most building sites, prototypes are still being built by hand. Digitalization opens up the possibility of overcoming this traditional production method: By forcing all those involved in construction to optimize the planning and complete it before the actual construction process. Today, a building can be planned and optimized virtually and precisely as a digital twin – before the realization begins. The computer can check thousands of variants on the digital twin overnight, of which only the best or most economical is then implemented at the construction site. The construction process can also be tested and optimized virtually before it actually takes place. This enables us to manufacture a perfectly mature product right from the planning stage, as is customary in other industrialized sectors, even if this is usually only one piece. Sensible planning has an influence on the construction process and vice versa, changed construction processes and construction methods, such as prefabrication, also have an extreme influence on planning. I used to supervise many private-public partnership projects where one was forced to think holistically. In my view, the separate areas of planning, construction and operation must grow much closer together.

C. G.: At present, the small-scale nature of the industry is indeed an obstacle. Unlike the automotive industry or the construction of ships – and a ship is ultimately a floating property – the construction industry is not organized as an industry, but as a trade and with micro-enterprises. This very German or even continental European phenomenon is as much an obstacle to innovation as the processes regulated in detail in the HOAI (Official Scale of Fees for Services by Architects and Engineers in Germany). At present, the small-scale nature hinders digitalization and networking leading to the industrialization of the entire sector in the construction industry.

C. G.: If the construction process were to change from on-site construction by many trades to a more logistically oriented assembly of quasi industrially prefabricated elements. The use of robots as well as 3D printing will also open up new perspectives and opportunities in on-site construction. In theory, a house could already be assembled from existing products and components in the digital model. Apart from the design, architects and specialist planners could then concentrate primarily on optimization, as they would be relieved of time-consuming routine tasks. Everyone involved in construction, from product manufacturers to the building trade professionals, must ask themselves what role they would like to play in this structure in the future. Because the job descriptions will also change dramatically.

C. G.: With the existing small-scale system, it is obviously not possible to create sufficiently affordable living space with an attractive architecture. Especially in multi-storey residential construction, it will therefore be necessary to plan and build with a higher degree of systematization in the future. In my opinion, brickwork is the best building material for creating the balancing act between individualization and Prefab 2.0. Because basically every brick is already a prefabricated element, a prefabricated part. The automated laying of masonry blocks at the construction site using powerful robots would combine efficient and individual on-site production with the economies of scale of production in large, profitable quantities, and at the same time mitigate the problem of a lack of skilled workers. Technically, the solution here is obvious and, in my opinion, will be ready for the market much faster than 3D printing for concrete. Sales processes will also change along with the processes on the construction site. The manufacturing industry should therefore think more in an interdisciplinary way and offer its customers tailor-made overall solutions instead of bricks with specific physical properties. New customer-oriented solutions could include house types with potential for individualization.

C G.: That is also my perception. Many product manufacturers are trying to boost sales of their products with very convenient tools. If they make the work of architects and specialist planners easier, the chance that their own product will be more likely to be included in tenders increases. But what will it look like in a few years‘ time when architects and specialist planners will no longer be selecting the product, but instead the computer will search for the individual building products using purely analytical-objective criteria for its model?

C. G.: There are no simple recommendations for action on the way to digitalization. That is why it is important not to be afraid of digital issues, but to see in them an opportunity. It is helpful to set yourself digital sub-goals that do not necessarily have to run in a straight line. The exchange with other industry stakeholders and with building users is crucial. What is important here is the joint consideration of how to generate real added value from the digital possibilities. This could consist, for example, of the future occupant of the building being able to view his or her planned house with the aid of VR glasses. Any change requests could then be incorporated directly into the virtual building model. Such tools are a first step on the way to digitalization. However, the interfaces should be designed to be compatible so that they can be integrated into a larger system at any time.

Fachbereich Bauingenieurwesen der Technischen Universität Kaiserslautern

www.bauing.uni-kl.de

Prof. Dr.-Ing. Christian Glock has been teaching and researching in solid construction at the Department of Civil Engineering at the Technical University of Kaiserslautern since 2017. From 1999 to 2017, Glock held various positions at the former Bilfinger Berger AG (now Bilfinger SE), first as site manager, structural engineer and project manager and later as managing director. As a member of the management board of the Group company Bilfinger Hochbau GmbH (now Implenia Hochbau GmbH) from 2013-2017, he was responsible for the areas of research, development and innovation, among others. Glock is active in various committees of DIN, CEN, DBV and DIBt and is a member of the supervisory board of plan-bauen 4.0 - Gesellschaft zur Digitalisierung des Planens, Bauens und Betreibens mbH as well as in the scientific advisory board and innovation think tank of the ZIA.