Engineering tool brings energy transparency into production

The new Simatic Energy Suite engineering tool enables companies to correlate energy consumption values in production plants with their automation processes. The energy consumption of production components, such as drives or controls, or even complete machines, is recorded, checked and displayed “live“, for example, on a Simatic HMI panel (Human Machine Interface) or the Simatic WinCC SCADA system (Supervisory Control and Data Acquisition). The recorded energy data can then be linked to production data.

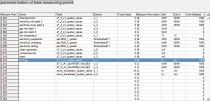

Simatic Energy Suite is suitable for energy-measuring components from the Simocode and Sirius series (low-voltage controls), Sentron (low-voltage energy distribution), as well as Simatic and Sinamics (automation and drives) from Siemens, for example the Simatic Energy Meters. Third-party measuring instruments are incorporated by means of open interfaces and, for example, input modules of the Simatic S7-1500 controller. Integrated into the TIA Portal V14 engineering framework, energy data recording with Simatic Energy Suite is easy to configure and quick to engineer. Users require very little time or prior expertise in order to familiarize themselves with the system.