Rapid Freeze/Thaw Durability Testing of Clay Brick

A faster new test method for the evaluation of freeze/thaw durability is presented. Compared with the test method according to ASTM C 67, this approach more accurately simulates the freeze/thaw cycles of masoned bricks. This report contrasts the new test method against other existing methods of durability validation. In addition to plant-fired bricks, plant-extruded bricks were lab-fired for testing. The findings indicate that the new rapid test procedure offers a very high level of validity regarding the anticipated freeze/thaw durability of brick saturated at five-hour boiling water absorption.

1 Introduction

1.1 Relating Physical Properties to Durability

The potential durability of clay building brick has been studied in some depth since at least the early part of the 1800’s [1]. A considerable amount of effort has been expended in the attempt to correlate physical properties to durability.

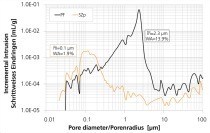

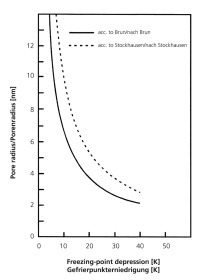

Properties such as absorption, capillary suction, porosity, pore size distribution, saturation coefficient and various strength measurements have all been investigated as potential indicators of durability. In the United States, the potential durability of brick is determined by meeting a set of criteria defined in ASTM standards. The use of these properties to predict durability derives from the work of McBurney in the 1930’s, but the use of the saturation coefficient to predict durability has been criticized extensively over the years [1, 2].

Currently, ASTM C 216 and C 652 use boiled water absorption, saturation coefficients and compressive strength to make an initial assessment of the potential durability of a brick. Brick that meet the specifications are classified as SW (severe weather) grade. It is also possible for a brick to meet a lower level MW (moderate weather) grade.

According to Robinson et al., the current specification for brick in ASTM C 216 accepts approximately 23% of non-durable brick and rejects up to 30% of durable brick [3]. Robinson also stated that no single physical property can be used to predict durability, since durability is a function of both the pore structure of the brick and the nature of the fired bond [4]. In other words, the pores determine how much water the brick can hold and how quickly it can absorb water, while the fired bond determines how well the brick can resist the expansive forces as the water expands on freezing.

In a wall, the brick typically become saturated through capillary suction when exposed to water from the environment (5)…