Recyclable clay bricks

Ziegelwerke Leipfinger-Bader (Lower Bavaria) is, according to the manufacturer, the first German brickworks to guarantee recycling for its solid masonry clay bricks and blocks. For many years now, the family-run company has been pursuing the goal of recirculating brick rubble from construction sites back into the value chain. A recycling facility specially developed for this purpose at its Puttenhausen site is now achieving this feat. The broken clay blocks and insulating materials are first cleanly separated from each other and then recycled. While the brick rubble is reused, for example, in greening roofs, the insulating materials are returned to production. “We see masonry bricks as a valuable material resource even beyond their first phase of life. With the development of our special recycling facility, we are delighted as a producer of building materials about this environmental breakthrough,” explains Thomas Bader, who heads the company.

Around 58.5 million tonnes of building rubble are produced in Germany each year. Around 10 million tonnes consist of bricks or mixes of materials with a high content of brick from demolition projects. Recycling can help preserve resources and reduce the quantity of waste produced. Here, the family-run company Leipfinger-Bader has been officially breaking new ground since September: “In our view, the leftover pieces from cut bricks from the construction site are also a valuable resource that shouldn’t go to waste,” explains Managing Director Thomas Bader. “For this purpose, we have built a dedicated new recycling facility in Puttenhausen. So, we are the first brickworks in Germany to offer integrated recycling.” In future, material from demolition projects is also to be accepted for recycling. A special service is the free collection of the brick rubble from the construction site. For this purpose, big bags are provided, in which the material can be properly packed and safely transported away.

Recycling demands innovative technology

The idea of recycling has been realized by the brickworks on the back of years of research and development. The challenge was first to break down the brick rubble with the insulation material into individual components. The solution lay in an old mechanical separation process that utilizes gravitation, mass and centrifugal forces – air separation. This process forms the heart of the recycling plant. Known from agriculture, it is not only able to sort the wheat from the chaff as the saying goes.

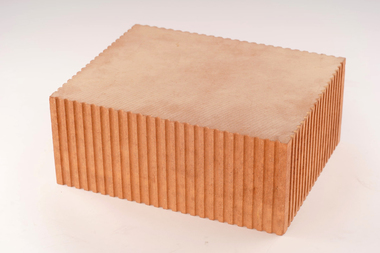

The construction waste initially broken up with the help of a screening bucket is fed into a wind tunnel, which opens two paths: lightweight insulation particles are extracted by suction upwards, while the heavy brick rubble falls downwards. Separated in a cyclone separator and then fine-screened, the insulating material is then ready to be reused as such. The principle functions both for mineral and wood fibres, which are used at Leipfinger-Bader as filling in thermally insulating Coriso or Silvacor clay blocks. In addition, the broken clay brick rubble is comminuted further and reused in different grades as substrate for greening roofs or path construction.

Sustainable company management as a maxim

In the spirit of sustainability, Leipfinger-Bader Brickworks is continuously optimizing all internal processes and products along its value creation chain. The complete recycling of its own masonry block waste is a highlight here. But environmental awareness already starts during the extraction of raw materials: former clay pits are always extensively renaturalized and biotopes created on the company premises.

As a participant in emission trading, the company also offsets the CO2 emissions from brick production. Fewer fossil fuels means less CO2: Therefore a flue gas purification system with heat exchanger and a highly modern kiln are used in production. The energy necessary for the brickworks’ operations comes from the company’s own solar park and the purchasing of green electricity. Every need for optimization in recent years could be determined precisely in accordance with DIN EN ISO 50001. “All measures have been designed to reduce our energy demand in all company departments. But our Unipor masonry blocks themselves contribute, too, as their high thermal insulation makes them efficient energy savers – now filled with recycled insulation, too” explains Bader.