Some positive effects of installing guide wheels

in rotary fans

In the brick and tile industry, rotary fans are the most frequently employed type of ventilation device. These air distributors generate high discharge velocities that help achieve major airflow turbulence in the adjoining brick setting. Together with the rotational motion of the air diffusers themselves, this results in uniform drying of the bricks. One problem, however, is that the swirl-impaired flow of air from the axial-flow fan causes a friction-induced pressure drop along the wall of the air diffuser.

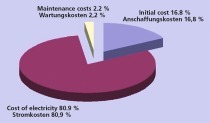

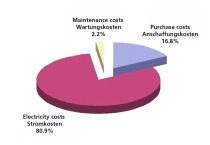

However, guide wheels known as flow straighteners have been in use for several years now for selectively redirecting the flow of air from the fan wheel blades. The discernible effect of flow straighteners is so great, that a one-size-smaller motor suffices for the same volumetric flow of air. Conversely, if the original type of motor is retained, a flow straightener will increase the volume flow by 10 to 15%. In the meantime, extensive experience has been gathered concerning the use of guide wheels in rotary fans. The results show that the positive effects are not limited to the factors electricity consumption and volumetric airflow. The improved depth of airflow impact makes the bricks at the rear of the setting dry more quickly. As a consequence, a frequency inverter can be used to further reduce the rotational speed of the motor and save even more electricity.

Dipl.-Ing. (FH) Erik Leu,

Robert Thomas Metall- und Elektrowerke GmbH & Co. KG