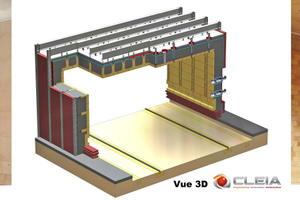

Technofast and Tradifast kilns from Cleia

The French plant engineering company Cleia offers two technologies for air-tight refractory kilns: the Technofast kiln and the Tradifast kiln.

The air-tightness of the kilns is ensured by fully welded metal sheets maintained at temperature on all sides, enabling firing under pressure and better regulation control. The kiln furniture is adapted to the positioning of the products in the kiln and the properties of the raw materials used. Thanks to the low porosity of prefired refractory pieces, these kilns offer very good chemical resistance to the flue gases produced during preheating.

Technofast kiln

The walls of the Technofast kiln are made of prefired refractory pieces with physicochemical properties and dimensional stability perfectly controlled during fabrication. Specially shaped roof slabs enhance heat exchange during the firing cycle. Technofast kiln wallsare quickly erected and require low masonry labour.

Tradifast kiln

The design of the Tradifast kiln is identical to that of the Technofast, but here a suspended refractory roof is anchored to external metal structure. The walls consist of masonry erected with refractory bricks and special refractory elements for the installation of the side burners.

Benefits

Cleia kilns offer the following special benefits

Proven design

The supporting structure can be erected locally

No double roof

Refractory pieces fit together for better roof stability

Possibility of reinforced thermal insulation

Control of firing process and consumption

Robustness and long lifecycle

Cleia recently installed a Tradifast, kiln, which is soon to be commissioned at the Wienerberger’s Acheneim brick plant in France.

The next kiln to go into operation will be Technofast kiln for the Guerrouache brick plant owned by the Argibordj Group in Algeria. Four more Technofast kilns are under construction in Algeria.

Cleia

www.cleia.fr