Utilization of Waste Heat and Combined Energy Systems in Brick Plants

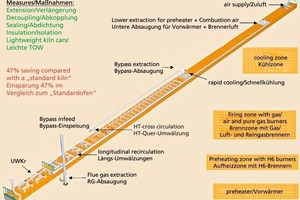

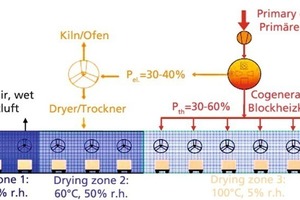

With rising prices for energy and an increasing portion of costs for drying and firing as the most energy-intensive process steps, measures for saving energy and the economical utilization of energy to achieve a reduction in energy consumption are regaining interest. Ranking first is the reduction of the specific energy consumption of kiln and dryer by means of process improvements, followed by the utilization of waste heat for other steps in the brick production process and finally the utilization of waste heat and the conversion into other usable types of energy.

1 Introduction

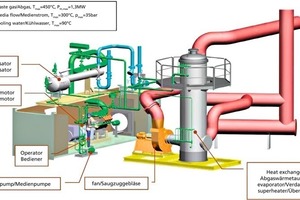

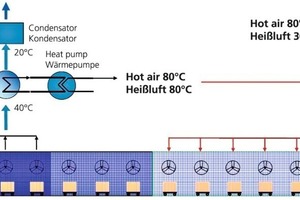

Owing to the combination of the heat systems of dryer and kiln, the dryer often remains undetected as the major consumer of energy in a brick plant. For the most part, the installation of alternative heating systems or the utilization of ambient air for drying do not appear attractive. In the simplest case, fuels with high combustion efficiency are used in brick plants as the primary energy resource for heating purposes. In a first alternative step it would be reasonable to take the primary energy resources for the generation of electricity and then utilize the generated waste...