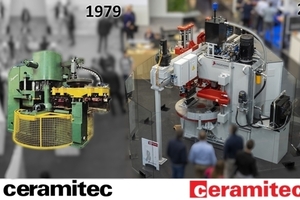

45 years later, Bongioanni launches the 9th generation of hydraulic presses at the Ceramitec Exhibition

In 1979, at the first Ceramitec exhibition in Munich, Bongioanni Macchine presented to the world the very first hydraulic press type IP4S, which revolutionized the market. Since then, we have continued to drive innovation in the field of hydraulic presses, combining experience and collaboration with the best companies in the industry to create advanced solutions. Now, after 45 years of progress and success, we are pleased to introduce the ninth generation of our well-known Hydromatic presses, the type IP92. This new model represents the climax of our commitment to excellence, developed in close collaboration with Bosch Rexroth and SEW to provide higher performance and greater efficiency.

The new press, with a pressing strength of 900 kN and a production capacity of 600 pieces per minute, is designed to grant high efficiency and energy saving. Thanks to the integration of a Rexroth 22Kw variable displacement hydraulic pump, the quantity of oil required for operation is significantly reduced, thus raising sustainability standards and reducing operating costs. Besides, the sturdiness and already long-lasting lifespan of the machine have been further improved through the application of finite element calculations (FEM).

The design includes SEW brushless motors for moving both the table with a diameter of 1500 mm and the loading and unloading system, ensuring precision and reliability in the positioning of the pieces. The loading unit, the trimmer head and the compressor of the press are equipped with a fall-prevention safety system, that further increases the safety during operation.

The configuration of the new press allows to maximize the operational flexibility, with the possibility of adjusting the press stroke for single or double stroke, and a height of the moulds pack of 350mm. In addition, it is possible to vary the hydraulic stroke, which reaches 400mm, depending on the type of mould used, be it made of rubber, plaster or steel. This feature ensures great adaptability to different types of production, while maintaining the quality and integrity of the finished product.

The Hydromatic press IP92 is not only a press but it is a completely compact, integrated and modern automated system that is also ideal to be installed in robotic production lines. This makes it a very flexible solution, perfect for companies seeking to maximize efficiency and minimize downtimes, setting new standards in the hydraulic press sector.

In conclusion, the unveiling of the new Hydromatic IP92 hydraulic press at the exhibition Ceramitec 2024 represents a proud moment for Bongioanni Macchine, demonstrating once again our commitment to innovation and quality in the heavy clay industry. With a completely revamped design and advanced functionality, we are ready to face the challenges of the future, consolidating our position as a market leader in industrial solutions. We look forward to welcome with open arms all those who were unable to attend the world premiere of our new press at the Ceramitec exhibition in Fossano.