About heat generation without natural gas and unfired building materials - spring Advisory Board meeting of the Research Association of the Brick and Tile Industry e. V. 2024

On 15 May 2024, the Advisory Board of the Research Association of the Brick and Tile Industry (FGZ) met for its spring meeting. The venue was the Hotel am Steinplatz in Berlin-Charlottenburg. The main topics on the agenda were the supply of heat without natural gas and clay bricks.

Barbara Fischer, Managing Director of the Association of Gas Transmission System Operators, discussed the current status of the German hydrogen core network. 9,700 kilometres of pipelines are planned. 60 percent are to be created by converting existing natural gas pipelines and 40 percent by new construction. The core network planning does not envisage an area supply; sub-networks would have to be provided by local institutions. As the primary customers are steel producers, the core network will only transport mixture-free hydrogen. The brick industry is not part of the core grid planning, as it is planned for an electrical perspective. However, a special solution for participation in the core grid has not been ruled out.

Hybit, a project to produce green hydrogen for steel production in Bremen, was the focus of the second presentation. Key Account Manager Hydrogen Marketing Frerk Lüschen from Bremer Wasserstoff GmbH, a joint venture between Stadtwerke Bremen and the north-west German energy group EWE AG, presented the project. A ten megawatt electrolysis plant is to be built at the Bremen Mittelsbüren power plant site to produce hydrogen and supply the steel production of ArcelorMittal Bremen. The construction and operation of the electrolyser pose challenges. Not only must the electricity procurement criteria for green hydrogen be met. Ultrapure water is also required for electrolysis. EWE‘s hydrogen projects also include tests on hydrogen storage in caverns.

Richard Lemke, Managing Director of August Lücking GmbH & Ck. KG, reported on the production and use of wood gas in the brickworks as a CO2-neutral and economically comparable alternative to natural gas. (You can find out more about this, including details of how it works and its cost-effectiveness, in the report in the upcoming ZI 5/24).

The fourth topic on the programme was clay building materials. Dr Anne Tretau, Materials Research and Testing Institute Weimar (MFPA), explained the current status and challenges. Earthen building methods have a long and successful tradition, for example in Yemen there are multi-storey earthen houses. After an overview of the relevant standards, she went into detail about DIN 18945. She presented the types of clay brick listed under this standard - moulded, mould-pressed and extruded clay brick - as well as the raw materials, application classes and requirements for the proportion of holes and webs, brick density and compressive strength, moisture and frost resistance. She also dealt with clay masonry mortar in accordance with DIN 18946 and the implementation regulations under DIN 18940, in particular weather protection.

The presentation was followed by a lively discussion. The chairman of the FGZ, Rainer Berentelg, reported on his own experiments in the production of clay bricks. The problem with clay as a building material is solely in the application. Richard Lemke seconded this and called on the brick industry to use its own existing expertise in handling clay to develop appropriate building materials. Clay building should not be left to competing building materials producers.

Four ongoing projects were presented under the following agenda item „project-accompanying committees“.

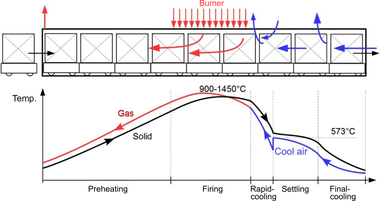

Dr Ralf Wagner, MFPA, presented the project “Microwave-assisted firing of brickwork products (01IF23193N), which began on 1 March 2024. The project has three objectives: (1) developing a process for microwave-assisted firing of brick products; (2) answering the question of how a balanced temperature profile can be achieved in the firing temperature range (850 °C to 1100 °C); (3) developing possible implementation concepts and future kiln technology for the brick and tile industry. The planned work packages include improved measurement setups for determining the temperature-dependent material properties up to 1200 °C. For successful firing with microwaves, the temperature gradients and thermal runaway must be controlled.

Dr Wagner also presented the project „Design of functional brick surfaces to influence the urban microclimate and building energy requirements (22226 BG)“ (see ZI 4/23, p. 38f.). Work package 4, “Increasing IR reflection through defined structures“, has currently been completed. It has been shown that defined structures have an influence on the reflection of infrared light. However, this effect is only slight in a two-dimensional form. For the final work package „Metrological investigation of the effects of the modified surfaces on the physical properties of the tile products“, Wagner requested and received the support of the project support committee. This involved the delivery of roof tiles for corresponding measurements in the demonstrator.

The third project presented, “Automated hyperspectral imaging and image analysis for sorting (22068 BG)“, ran with an extended project duration until 31 May 2024 and was presented by Jurij Walz on behalf of Dr Elske Linß (MFPA) (see ZI 4/2023, p. 39). Walz then presented the outline for a follow-up project: „Optimisation of optical brick sorting and estimation of the pozzolanic activity of masonry rubble to improve the recycling process using multispectral and image-analytical parameters“. The project is scheduled to run for 24 months. The aim is to further understand and optimise the sorting process. The development goal is a modular, hyperspectral sorting and testing system for the reliable differentiation of brick types and estimation of pozzolanic activity.

Dr Anne Tretau presented the last project, which started on 1 May 2024: “Influence of process control on the energy demand of microwave dryers (01IF23309N)“. The aim is to gain a deeper understanding of the process-controlling, complex interactions between electrodynamic (energy input) and thermodynamic processes (heat and water transport) as well as the mechanical properties (strength as a function of temperature and humidity). These present the process management with the challenge of drying in a way that is gentle on the product while making maximum use of the energy output. Tretau described the work packages. She concluded by pointing out that electrification would require a comprehensive reorganisation of the plant’s machine arrangement and discussed the economic and technical challenges.

The autumn meeting of the FGZ Advisory Board will take place on 13.11.2024 in Berlin.