Ammonia (NH3) as a fuel in the clay brick and tile industry - Project meeting on 23 September 2024

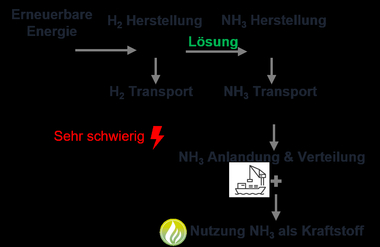

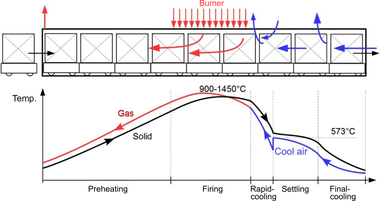

The roadmap for a greenhouse-gas-neutral brick and tile industry in Germany signposts a climate neutrality route intended to lead to a CO2-free brick and tile industry by 2050. Along with other conditions, key goal in this roadmap to climate-neutrality is the total replacement of fossil fuels with renewable energy sources. Especially for high-temperature processes, alternative fuel gases present an interesting option for decarbonization. The focus here is on green hydrogen. Besides the use of green hydrogen as fuel gas, its use as educt gas for the production of green ammonia is an interesting technological route. Green ammonia can be produced by means of ammonia synthesis when the educts nitrogen and hydrogen are recovered from renewable energies. Especially with regard to transport and storage of the required energies, ammonia boasts a considerable advantage over hydrogen. Hydrogen can only be liquified at a temperature of -252 °C. Ammonia, on the other hand, can be liquified already at -33 °C under standard pressure, and even at 20 °C at a pressure of 9 bar.

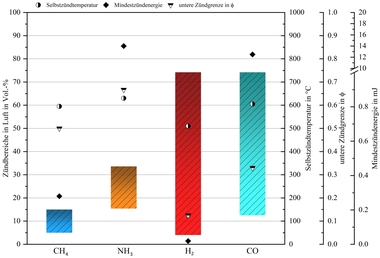

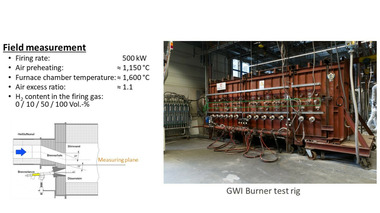

In the research project “Ammonia as a renewable fuel in the clay brick and tile industry”, the Institut für Ziegelforschung Essen e.V. (Brick and Tile Research Institute) is currently collaborating with the Gas- und Wärme-Institut Essen e.V. (Gas and Heat Institute) to investigate the combustion behaviour of ammonia, as well as its effects on brick and tile quality. Following basic research on ammonia combustion, the first firing tests were conducted on laboratory scale. Ammonia has a heating value of Hi = 14.14 MJ/mN³. This is higher than the heating value of hydrogen, which is Hi = 10.80 MJ/mN³. Its adiabatic flame temperature of Tad = 1 798 °C, however, lies well below that of hydrogen (Tad = 2 106 °C). Ammonia also has a much lower flame speed and a much higher minimum ignition energy. Questions therefore arise as to whether the required process temperature can be reached with the much lower adiabatic flame temperature and what challenges may result with regard to flame stability. On account of the fuel-bound nitrogen, high NOX emissions can also be expected.

First tests on laboratory scale have shown that pure ammonia combustion is possible. For cold ignition, however, natural gas or hydrogen was used, with ammonia subsequently being gradually admixed. The NOX emissions are heavily dependent on the burner geometry. With the help of commonly applied reduction measures, however, these emissions can be kept in a moderate range. The primary objective was to determine possible solutions for stable ignition and combustion of NH3 based on suitable mixes. In the next step, ammonia firings were performed on semi-industrial scale with the use of two lance burners employed in the brick and tile industry.

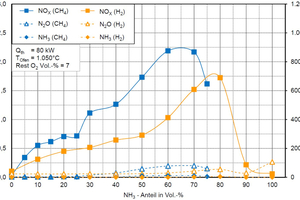

»Figure 1 shows the NOX emissions, N2O and NH3 slip for different gas mixes. Here, ammonia was added gradually in 10-vol% steps into natural gas and hydrogen. It can be seen that the NOX-values for an ammonia content of 70 and 80 vol% reach a peak at a value of around 2 250 mg/m³ (oxygen reference value 17 vol%) and then fall. It can also be seen that admixture in natural gas is only possible up to 75 %. With admixture in hydrogen, 100-% ammonia combustion is possible. The resulting N2O and NH3 emissions are then particularly harmful for the environment. Hence, these must also be eliminated as far as possible.

To investigate the effects of ammonia on the brick quality, first four fuel gas configurations were defined: 100 % natural gas, which serves as the reference firing, a mix of natural gas and ammonia in a 50-vol% ratio, a mix of hydrogen and ammonia in 50-vol% ratio, as well as 100 % ammonia. From the three available clay bodies, first model facing and clay blocks as well as roofing tiles were prepared. These were then fired in line with the prescribed firing curves, with the above-mentioned firing gas configurations in a test kiln. After firing, the following product properties are to be tested: the colour difference, the compressive strength of the facing bricks and clay blocks, the flexural strength, which is significant particularly for roofing tiles, the shrinkage, the firing loss and the density.

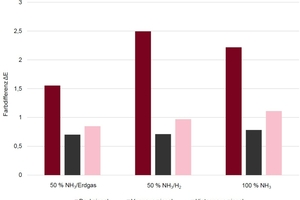

In the first step in the tests of the effects on product quality, the appearance of the bricks and tiles was investigated. To this end, the colour difference was determined with a spectrophotometer. The oxygen content in the kiln has a major influence on the colour of the bricks and tiles. During the test firings with all firing gas configurations, this ranged from 7 – 8 vol% O2. For the determination of the colour difference ΔE, bricks and tiles fired with pure natural gas were used as a reference. The values shown in »Figure 2 were measured.

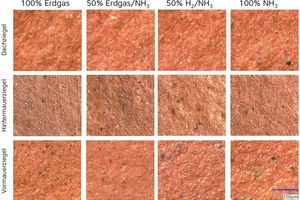

As can be seen in »Figure 2, most values are below ΔE = 1. This colour difference is imperceptible to the eye. Values between 1 and 2 are perceptible under close scrutiny. Accordingly, it can be said that different firing gas mixes do not have any influence on the visual appearance of the products. Further, the samples were analysed under a microscope. As »Figure 3 shows, no differences in colour can be detected.

In the further course of the project, technical material analyses will be carried out.

The participants at the project meeting were able to get an idea of the test procedure and the change in the flame during the demonstration of a lance burner with different NH3 admixtures.

The project is funded by the BMWK via the Industrial Collective Research Programme (IGF), project number 22893.