Climate-neutral firing process 4.0. in the brick and tile

industry

Keller sees climate neutrality in the manufacture of heavy clay products and digitalization in the brick and tile industry as the main challenges for this sector. As a specialist in machine and plant engineering for the heavy clay industry, Keller is taking on the „Green Challenge“ and has set itself the goal of transforming the industry sustainably in the future together with brick and tile manufacturers and partners. The following article explains the current status of research and development results for a climate-neutral production process and provides an overview of further development opportunities for saving energy.

Introduction

The brick and tile industry has been under enormous pressure to make changes for some time now. The legislator has stipulated greenhouse gas neutrality by 2045 in the Climate Protection Act. This is to be achieved at European level by 2050. The Federal Association of the German Brick and Tile Industry has outlined key steps for this in its Roadmap 2021.

How do we manage this?

The answer was and remains: „Regenerative“ - i.e. with the help of hydrogen, electrification, biogases or synthetic gases, biogenic porosification agents and in addition with storage technology.

1. Hydrogen

Keller has successfully conducted extensive tests as part of a research project with the brick manufacturer Hagemeister in Nottuln, the Institute for Brick Research in Essen, the burner manufacturer Kueppers Solutions and the VDEh industrial research institute. The aim was to develop a new burner technology that can be operated either with 100 % hydrogen, 100 % natural gas or any mixture, i.e. a „dual-fuel burner“ with the option of the highest possible substitution of natural gas with hydrogen. This should provide proof of the successful use of hydrogen in series production at the clinker plant. For this purpose, a test burner group with hydrogen went into operation on the Hagemeister kiln in August 2023, which was operated for several weeks both in the prefire and in the main fire.

Following the successful completion of the tests, it can be said that Keller has gained extensive experience with the firing of bricks with hydrogen, both on the process side and on the product side. Keller can provide a bi-fuel burner technology (dual-fuel burner) that is suitable for operation with 100 % natural gas, 100 % hydrogen or any mixture in between. This burner technology achieves a comparable flame length and flame temperature in hydrogen combustion compared to natural gas. Keller can provide the necessary control technology for such a plant, taking into account the rules and regulations to ensure safe operation.

The questions remain: „Where will hydrogen come from in the future and at what price?“

The industry‘s clear expectation is that a hydrogen infrastructure will be created and that hydrogen will be available at a competitive price.

If, on the one hand, there is proof that hydrogen can be successfully used as a fuel in the dryer and kiln and, on the other hand, that self-generated „green electricity“ is available, then hydrogen production, i.e. electrolysis and, if necessary, storage, is missing in between. The main electrolysis technologies are PEM - Polymer Electrolyte Membrane and AEM - Anion Exchange Membrane. Both technologies have their pros and cons. The devices often have a modular design and can therefore be easily adapted and controlled in terms of power. Power values of 1 to 5 MW in one container are possible. The efficiency of both systems is approx. 65 % if the calorific value of the H2 output side is set in relation to the electrical input power. The waste heat is present at a temperature level of 50 to 60 °C in the form of water or air. If this waste heat can be used, the cells achieve a system efficiency of over 90 %.

Let‘s consider the global production of H2. It is likely that hydrogen for Europe will in future come from countries such as Africa, Australia or Saudi Arabia, countries where the sun shines much more constantly than in Europe.

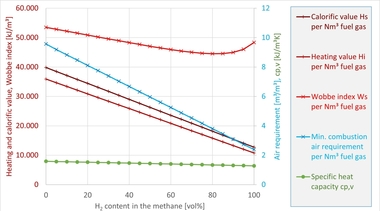

The disadvantage is that the transport and storage of H2 is expensive, as the calorific value per cubic metre is significantly lower than that of natural gas.

It makes sense to liquefy the hydrogen, as is also done with natural gas known as „LNG“.

The liquefaction of H2 takes place at temperatures below -253 °C. Thus, the energy expenditure for liquefaction is high. A chemical binding of H2 in the form of ammonia (NH3) can provide a remedy and be economical. NH3 can be liquefied at -33 °C, or at 20 °C at a pressure of 9 bar.

In fact, ammonia is already the most transported chemical in the world today.

For final use, ammonia must be treated in a cracking process (2NH3 => N2 + 3H2) or it can be burnt directly without cracking. However, ammonia is slow to ignite and has a lower flame temperature and flame speed than natural gas. Keller is cooperating with the Gas and Heat Institute Essen as well as the Brick and Tile Research Institute in Essen to find a solution for the combustion of NH3.

2. Electrification - our experiences

Duct heaters are available on the market with output temperatures of up to 800 °C.

They can be used, for example, for recirculation circuits for the dryer and the kiln.

Up to now, hot air generators have achieved output temperatures of up to 1,100 °C.

If the wire of electric heating rods is made of FeCrAL, it should anneal at max. 1,150 °C. It then has a service life of 5 years. 50 °C more annealing temperature halves the service life. By adding molybdenum, a temperature of approx. 1,250 °C can be achieved for the filament.

In addition to drying and firing, other process steps can also be electrified, such as film wrapping with a shrink-wrapping machine. Keller has supplied such a machine for shrinking film for packaging roof tiles on a Euro pallet. A film with a thickness of 130 µm is then shrunk. The connected power is 259 kW and the energy requirement per shrinking process is 2 kWh of electrical energy.

What are the next steps in electrification for Keller?

Keller, together with 3 partners, will carry out a field test on the use of a hot gas generator with a resistance heating principle and an output temperature of 1,500 °C as part of a research project. The corresponding funding applications have been submitted. The material of the resistor that is made to glow is no longer metallic, but ceramic.

As part of this project and beyond, Keller will of course be looking at what effects the use of hot gas has on ceramic firing, in particular on product properties.

Keller is also currently researching several electrification applications on its own initiative, including induction heating in pipes.

3. Alternative fuels - biogas or synthetic gases

The use of wood gas can be a suitable alternative, provided that sufficient waste wood is available near the plant and at an attractive price. If necessary, the wood gas must be compressed in order to burn it directly in the kiln at temperatures of 150 - 200 °C. For this purpose, Keller offers the CF45 burner with the appropriate valves that are adapted to the temperature and the wood gas.

4. Energy storage system

If processes or regenerative energy production take place periodically and energy is therefore dissipated at one time and supplied at another, a high-temperature heat accumulator makes sense. The storage principle is based on several parallel layers of storage material, which is normally quartz sand with a grain size of 1 to 3 mm. However, broken bricks and tiles are also conceivable as a storage material. A horizontal air flow through the storage layers is used for charging and discharging. The storage capacity per module is up to 20 MWh. The storage units can be cascaded. The temperature in the heat accumulator can reach up to 1,000 °C.

A high-temperature heat accumulator can be used to temporarily store surplus process energy or to store green electricity using the „Power to Heat“ process.

5. Increasing energy efficiency

The points mentioned so far, i.e. the use of hydrogen, electrification, the use of alternative fuels and the use of high-temperature heat accumulators, must be preceded by a joint effort to increase the energy efficiency of existing plants, which ultimately leads to the decoupling of kiln and dryer. This is a key requirement on the road to CO2 neutrality, because „every kWh not consumed is CO2 neutral“.

The following measures, among others, are possible to increase energy efficiency:

Kiln circulation systems in the heating and cooling zone or geometrically long heating and cooling zones with the aim of reducing the air balance in the kiln and increasing the temperatures of the exhaust air flows.

Minimizing false air flows (car joint sealings, sand seal, buildings).

The use of preheated combustion air or/and the use of pure gas burners.

Oxygen control in the kiln combustion zone with the aim of reducing the supply of external combustion air to a minimum. We want to use the air that is available in the kiln.

Lightweight kiln car decks to reduce exit losses.

Energy recovery from the wet air and the flue gas, if necessary in combination with the use of a heat pump. This allows energy to be partially recovered from unavoidable sources of loss.

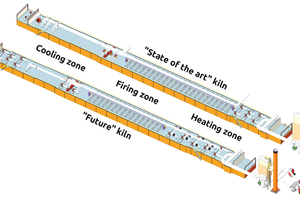

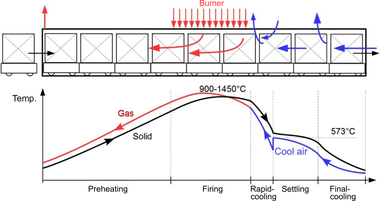

Keller has compared two kilns under the keyword „decoupling“. One is a „state of the art“ kiln, i.e. the way it is still built today, and the other is a „future“ kiln.

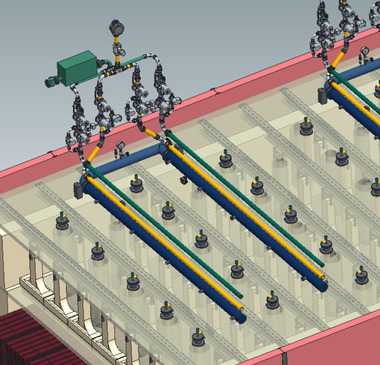

There is no classic final blow-in in the cooling zone of the „future“ kiln. The cooling air is supplied via circulation fans and is therefore controlled, targeted and highly efficient. The reduced air volume is extracted via the low temperature offtake and led to the kiln past the temperature range of the modification of the free quartz through a bypass pipe. Rapid cooling takes place via circulation fans with fresh air and/or process air from the aforementioned bypass. The hot air from the high-temperature offtake is not led to the dryer but past the main firing zone to the front and into the heating zone of the tunnel kiln. Via circulation fans, the energy is then fed to the products to be heated. Part of the process air from the cooling zone flows into the main fire as preheated combustion air. There, pure gas burners use the oxygen in the tunnel kiln atmosphere.

Numerous recirculation circuits operate in the heating zone of the „future“ kiln. The energy from the cooling zone is coupled in here. If necessary, electric heating registers can be installed in the recirculation circuits to provide additional energy. The burner plant on the tunnel kiln ceiling starts much later and at a higher temperature level. A polymer heat exchanger is available to recover the energy from the flue gas.

The total energy saving potential of the „future“ kiln is in the range of 20 to 40 %, depending on the product and setting geometry.

6. CO2 absorption

Certain production processes in brick and tile manufacturing traditionally require the use of CO2-emitting fuels, such as coal firing in facing brick production. One conceivable way of avoiding CO2 emissions in such a production process is CO2 capture with an absorption plant and subsequent methanation. The CO2 obtained is combined with hydrogen (CO2 + 4H2 => CH4 + 2 H2O) and converted into synthetic natural gas (SNG). The resulting natural gas can be used for the drying process, for example.

7. Pure gas burners

The supply of external combustion air can be completely omitted when using pure gas burners. In relation to the individual burner, around 30 % energy can be saved. The throw distance of the Keller HT pure gas burner is approx. 2 m. Due to the Venturi effect of the pure gas burner, the circulation rate is 350 m³/h.

The Keller HT pure gas burner can be used for a variety of fuel types such as natural gas, propane gas, hydrogen and mixed gases. It is suitable for a temperature range greater than or equal to 750 °C.

8. Predictive energy management system

If we consider the energy flows in the brickworks of the future, it quickly becomes clear that energy management will become much more demanding and that an intelligent and predictive linking is essential. What does this mean?

Today‘s tunnel kilns run continuously - 24/7 - and therefore also emit energy continuously. The dryer, on the other hand, does not run continuously in every plant. The energy requirement is discontinuous at the latest when using a chamber dryer. The first fluctuations are emerging. A high-temperature heat accumulator can be an effective technical solution. Furthermore, every brickworks has machines with a discontinuous demand for electrical energy.

On the other hand, more and more renewable electrical energy is being generated directly on site with the help of PV systems and wind turbines. These sources also produce discontinuously.

Since storing electrical energy is expensive, either hydrogen or heat can be generated from it. These media need to be stored and retrieved when required.

Ideally, the weather forecast should also be included in an intelligent energy management system. What is the solar and wind forecast for the next few days and which impact will this have on the plant‘s energy management? Production management must also take into account which products are produced or required at what weights and when.

The current cost situation on the electricity market should also be taken into account. At which times is electricity on the grid expensive, and at which times is it cheap?

An energy management system of the future must be able to process all this data in order to deduce measures to reduce energy consumption and energy costs.

This will also be a major challenge in a brickworks of the future.

For further information, please feel free to contact: