Climate-neutral firing process in the brick and tile industry – possible for us?

We say “yes”, it can be done. We clearly realise that this is a very big challenge for everyone involved. Together we need a lot of commitment and courage to achieve this goal.

Introduction

As we remember, we jointly wrote into the roadmap of the brick and tile industry a CO2 neutrality by 2050. The legislator has moved the deadline forward by another five years via the Climate Protection Act, thus prescribing greenhouse gas neutrality by 2045.

Due to the much changed geopolitical situation, it is now difficult to calculate how energy costs will develop in Germany and Europe.

Therefore, the urgency of improving energy efficiency has increased extremely. Climate catastrophes such as those in the Ahr valley or in Pakistan, as well as the “winter drought” in many European countries, show the extent of global warming and the urgency of greenhouse gas neutrality.

How do we manage this?

Only regenerative - i.e. via hydrogen, electrification, biogas, synthetic gases and biogenic pore-forming materials.

Electricity produced from photovoltaics or wind is currently one of the energy sources that is calculable in terms of cost. Generating one’s own electricity is seven to nine cents/kWh for photovoltaic electricity and is an economical alternative.

Hydrogen is currently still around 18 cents/kWh for self-production from photovoltaics and electrolysis.

For Germany, it is already clear that a significant proportion of the hydrogen required, or its derivatives such as ammonia and methanol, will have to be imported. As the hydrogen proportion increases, the economic efficiency will improve.

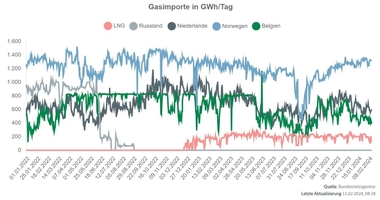

The price of natural gas is subject to strong fluctuations, extreme dependencies and it is unpredictable how the price will develop in the long term.

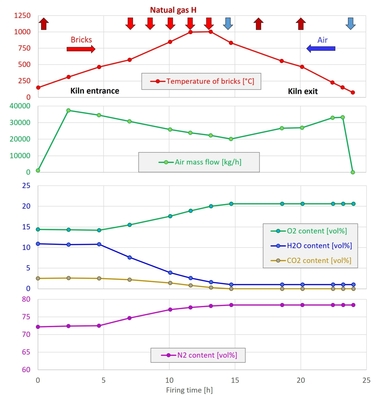

1. Hydrogen

Hydrogen is one of the primal elements of our planet. It is number one on the periodic table of elements and may soon be number one on the list of fuels as well.

Keller has been working on the topic of hydrogen since the end of 2020 and is a member of a research association consisting of five partners from North Rhine-Westphalia. These are institutes, burner manufacturers, brick and tile producers as well as plant manufacturers.

The common goals are a new burner technology for 100 % hydrogen or optionally natural gas operation (dual fuel burner) and the substitution of natural gas with hydrogen to the highest possible degree.

In May this year, the first burner group will be ready for use on an existing kiln in the brick industry. Based on preliminary tests, Keller is optimistic that the firing results will be positive.

2. Electrification

We see different possibilities for electrification. For this purpose, firing tests were conducted with wall-mounted heating registers and with electric heating rods in order to gather experience on the possible applications of the devices.

According to the analyses, electric heating rods can be used economically up to approx. 800 °C firing chamber temperature. The heating wire glows at approx. 1,150 °C. At this temperature, the working life is approx. five years. This is halved when the glow temperature is increased by 50 °C.

The smaller the delta T between the firing chamber and the heating wire, the lower the remaining heating capacity.

Duct heaters can be used, for example, in recirculation circuits on the kiln or as auxiliary heating for the dryer.

Hot air generators can also be used for hot air injection in the kiln. However, the temperature range is limited, as the outlet temperature is max. 1,100 °C.

Another alternative is the electrification of sub-processes, e.g. in the packaging area. Keller has already supplied an electrified film hood machine for this purpose.

Microwave drying is a technique that has been known for many years. It can also contribute to the electrification of sub-processes. Keller built a microwave pilot plant in 1998 in which six magnetrons of two kW each were installed. They were used to “preheat” the products to approx. 60 °C before they were transferred to a conventional continuous dryer. Positive results have been achieved in numerous preliminary tests. The challenge lies in integrating this technology into existing plants, whether as upstream dryer modules or also for raising the temperature of the clay column as well as of individual products in the area of the feed to the tunnel dryer car loading station.

3. Increasing energy efficiency

The first and essential step towards CO2 neutrality must be to increase energy efficiency, which ultimately leads to decoupling the kiln and dryer as far as possible.

In order to achieve the goals, the following topics are to be worked on in the existing plants:

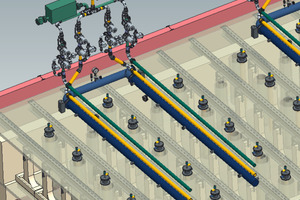

1. Air circulation

The air circulation serves to increase the heat transfer with the goal of getting by with lower longitudinal flow rates, i.e. a lower air/brick ratio in the kiln.

The circulation systems built by Keller represent a plant-specific and thus optimised solution. Ceiling-to-ceiling, ceiling-to-side and side-to-side systems have been implemented and ensure ideal setting flow with improved alpha values.

For new plants, a longer cooling and preheating zone should be considered in order to increase efficiency through a temporally prolonged heat transfer and thus achieve lower air/brick ratios.

2. Use of the preheated combustion air

A long-known measure for increasing energy efficiency is the use of preheated combustion air. Even better than preheated combustion air is the exclusive injection of gas into the kiln using the ambient air as combustion air. This requires the so-called clean gas burners. Keller has two solutions to offer: the Keller CF 10 burner with gas injection and a low purging air volume, and the newly developed Keller HT clean gas burner, via which only gas is injected and the ambient air is mixed in via a specially shaped burner head.

3. Reduction of the exit losses of the kiln

Keller already conducted tests on the mobile beam kiln in the 1990s. With the help of this technique, the exit losses can be significantly reduced, as the tunnel kiln car masses entering and leaving the kiln are reduced to a minimum.

In standard existing plants, the exit losses via the kiln car are approx. four to ten percent of the kiln’s thermal energy demand. A weight reduction of the existing tunnel kiln cars by up to 50 percent seems realistic, which would reduce the exit losses to two to five percent.

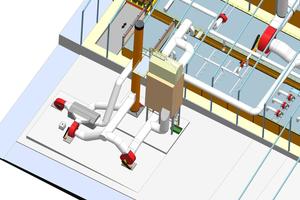

4. Decoupling of kiln and dryer

If the decoupling of the kiln and dryer is completely or at least predominantly successful, new and thus regenerative options are available for supplying energy to the dryer. One possibility is the use of a heat pump. The condensation energy contained in the wet air is used and transferred to a higher temperature level with the help of the heat pump. Single-stage or multi-stage compression heat pumps can be used here. With these pumps, it makes economic sense to achieve temperature levels of approx. 110 °C with a coefficient of performance (COP) of approx. three.

5. Energy recovery by flue gas

Another interesting possibility for energy recovery lies in the flue gas. The flue gas losses of a kiln are about 25 percent of the kiln’s energy demand. Recovery therefore makes sense and can be carried out with the familiar thermal oil heat exchangers or alternatively with polymer heat exchangers. With polymer heat exchangers, half the energy can be recovered without any problems if you deliberately drive into the acid dew point. This would thus be a recovery of 12.5 percent of the total kiln energy. This is available at a temperature level of approx. 110 °C and can be optimally used for the drying process.

6. Wood gas use

Wood gas is a biogas produced by pyrolysis. With wood gasification, approx. 94 percent of the energy used can be converted into wood gas. The calorific value is approx. three kWh/m³ and thus about 1/3 of natural gas, i.e. it is necessary to intervene in the plant technology because three times the gas quantity must be passed through.

A prerequisite for meaningful use is that sufficient used wood is available at anattractive price in the vicinity of the site.

7. Control and regulation of energy flows

Another measure to increase energy efficiency is a “smart” control system. It is easier to coordinate energy flows and regulate processes more precisely. Dependencies must be coordinated in advance. This is especially true when regenerative energy sources are integrated, as they are not constantly available. The sun doesn’t always shine and the wind doesn’t blow at all times either.

For further information, please feel free to contact: