Energy concepts for kiln and dryer

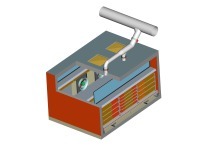

Based on comprehensive measurements, a cooling-zone energy balance was compiled for a tunnel kiln at a roof tile factory. The data yield enabled development of a process in precise alignment with the plant‘s own specific parameters. The...