40, 50, 65: numbers that pack a punch

Deppe sets standards in sustainable building with new Lean Brick 19.03.2025Now in its fifth generation, the clinker brick manufacturer Deppe Backstein from Grafschaft Bentheim develops and produces long-lasting bricks that are both aesthetic and functional. The brick manufacturer has already realised a number of measures on its way to CO2 neutrality. These range from the generation of electricity from renewable energies to the 100 per cent recycling of waste into the production cycle, the renaturation of all local clay extraction areas, the use of electrically powered shrink-wrapping technology including recycled film for packaging the bricks and the multiple use of energy through, among other things, kiln waste heat and a flue gas heat exchanger. In this way, Deppe has ensured in recent years that its clay building materials are produced in an increasingly climate-friendly way and has made a significant contribution to a more climate-friendly planet.

With the aim of making the product portfolio even more responsible and ecological, the Deppe team, under the leadership of Managing Director Dr Dirk Deppe, has been conducting a series of tests for some time to further minimise the carbon footprint of the bricks.

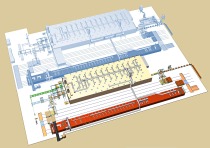

The resulting Lean Brick is a milestone in the field of ecological facing bricks. This is because the products in the Lean Brick range measure 240 mm x 65 mm x 71 mm and are therefore characterised by a 50 mm reduction in depth. This means: 40 per cent less volume, weight, transport costs and CO2 emissions compared to conventional facing bricks in standard format. At the same time, the Lean Brick fulfils the same quality and design requirements as conventional facing bricks in the familiar formats. The German Institute for Building Technology (DIBt) has now granted approval to realise double-skin facing brickwork with a facing brick shell of just 65 mm, i.e. with the Lean Brick.

Less is less is more ... sustainability

Less - this applies to all aspects of Lean Brick - from production to processing on the construction site. Because by reducing the volume, less raw material is required, less energy is used to fire the brick, less weight is transported and transport routes are therefore less harmful to the environment.

Less is less is more ... space

The Lean Brick also offers considerable advantages on the construction site. The brick is significantly easier to handle due to its reduced volume. In addition, less mortar and jointing material is required. The reduced volume of the brick also increases the usable area. The Lean Brick is therefore ideal for buildings in urban environments and for buildings where space optimisation is a decisive factor. The slim dimensions of the Lean Brick offer more space for insulation without having to increase the depth of the external wall. This opens up even more possibilities for all planners and building owners in the design of the façades as well as in the conception of the room programme.

Uncompromisingly recyclable

Like all Deppe bricks, the Lean Brick is fully recyclable, whether reused or as a secondary source of raw materials for the production of new bricks. The Lean Brick is available as water-struck and extruded facing bricks in all colour variants.

Facts, figures and data at a glance

The new Lean Brick format sets standards for resource-saving, cost-efficient and environmentally friendly construction - without compromising on quality and design.