Rotho‘s motto:

“Saving energy – always one step ahead”

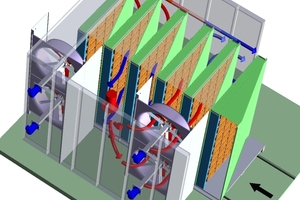

The patented Quatro construction, for example, has been used in more than 50 chamber/continuous-flow dryer applications. Compared to brick-and-mortar structures, this prefab system unites high leaktightness with very good insulation and low stored-heat volumes.

Rotho‘s MixAir rotary fan with integrated guide wheel and energy-efficient motor was developed for the ventilation engineering sector. The Rotho MixAir rotary fan enables use of smaller motors for a given volumetric flow.

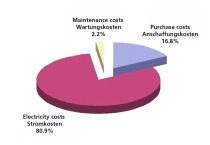

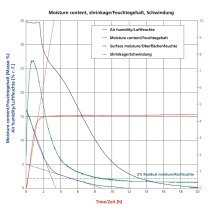

Rotho has invested special effort in recent years in moving their fast-drying technology forward. The resultant XStream quick dryer lets producers save 10 to 20% thermal energy and roughly 60% on electricity compared to conventional drying methods.

The particularly efficient EcoDry low-energy dryer is also based on rapid drying technology. With an EcoDry quick dryer, thermal energy consumption for drying can be reduced by approximately 70%. This is presently the only such pro-cess to offer such huge potentials for energy conservation in brickmaking.

Hall B5, Stand 429