Recent experience with low-energy drying of backing bricks

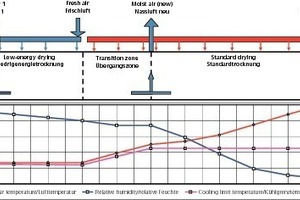

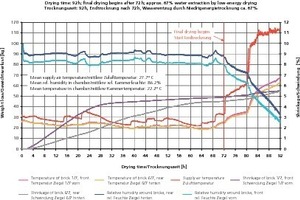

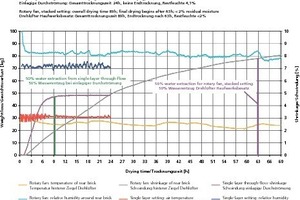

The practical implementation of low-energy drying at several different brickworks is featured here. Also presented is a fast-drying process with which to implement low-energy drying in new dryers with short drying times and acceptable dimensions. Finally, a profitability analysis shows that the planning for any new dryer(s) should always include an ambient-air drying component.