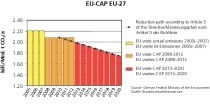

SBBC Societé Briqueterie Bati Chaouia is one of the biggest brickworks in Morocco. Beginning in 2008, both energy efficiency and fuel switch measures were technically implemented in the production process, resulting in a significantly reduced carbon footprint of the facility. The greenhouse gas emission benefit from this project was also deployed for consideration of CDM, that is the Clean Development Mechanism under Article 12 of the Kyoto Protocol. Based on this history, a case study is presented where technical measures are assessed against carbon benefits achieved and their embedding in current footprinting standards, project-related carbon mechanisms and emission trading schemes are described.

Norbert Heidelmann, TÜV Rheinland Energie und Umwelt GmbH, Cologne, Germany