Randers Tegl lowers its carbon footprint and sets new standards for CO2 reduced bricks

Through a new digital climate data solution, targeted changes in production and a transition to biogas, Randers Tegl has in just one year reduced the documented carbon footprint of its bricks by an average of almost 50 percent. This means that the group can now showcase the newly produced bricks with the lowest CO2 footprint in Denmark - and according to the sales manager, perhaps even the world.

Architects and contractors will now find it even easier to benefit from the aesthetic and functional qualities of bricks while meeting the increasingly stringent climate requirements. Randers Tegl is currently launching the latest climate data - the so-called Environmental Product Declarations (EPDs) - for the group‘s brick products, and according to the company this is some of the strongest data on the market.

This is partly due to the fact that over the past year Randers Tegl has phased in a newly developed digital EPD solution that enables the company to quickly and easily create unique EPDs for each individual brick in the range. This is unique in the industry and means that Randers Tegl can gain full insight into the composition of the specific brick‘s total Global Warming Potential (GWP) value with just a few clicks and then initiate targeted efforts to reduce the carbon footprint.

At the same time, as of 1 January 2025, Randers Tegl has entered into an agreement to supply biogas to all the group‘s brickworks. Overall, this means that the company has lowered the GWP value of more than 150 product numbers, shaving almost 40 percent off the previous record for the brick with the lowest GWP value in the country.

„This is very significant, and in fact, we are not aware of any newly produced brick products with lower GWP worldwide than ours. That said, it‘s not enough for us to have the greenest bricks. The crucial thing is that we now have a wide range that is very competitive compared to other facade products, so that bricks can contribute with their fantastic qualities in terms of aesthetics, longevity and minimal maintenance requirements,“ says Kenneth Moesgaard Poulsen, Sales Manager at Randers Tegl.

The development over the past year means that Randers Tegl can now boast a GWP value of 4.55 kilograms of CO2 equivalents per square metre for the group‘s classic red brick, which is the newly produced brick with the lowest carbon footprint. Last year, the GWP of the corresponding product was 9.52. The newly produced bricks also move significantly closer to a recycled brick, which in Randers Tegl‘s range has a GWP value of 2.42.

Data creates a huge incentive for optimisation

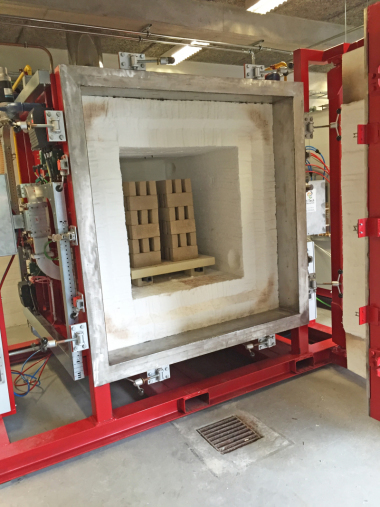

In addition to the conversion to biogas, the specific reasons for the significant CO2 reductions can be found in the fact that Randers Tegl, based on the insights from the digital EPD solution, has adjusted everything from the lime content in the bricks to fuel consumption and waste reduction at the brickworks.

„We can now see in black and white where the shoe pinches in terms of CO2 impact and with which investments we can achieve the greatest possible reduction. It‘s a game changer for us. Also because the tool allows us to replace some of the generic data that still characterises the common EPDs in the brick industry with our own specific data,“ says Kenneth Moesgaard Poulsen and continues:

„For example, we have replaced generic data for clay excavation, which was previously based on an example from Germany, with our own process. This makes the EPD much more specific, which creates a huge incentive for us to optimise all the parts we possibly can, simply because it allows us to differentiate ourselves. It will also be of great importance for our future product development, as we already know in advance exactly which components we need to combine to get the desired climate data.

With the phasing-in of the new digital solution and the transition to biogas at the brickworks in place, Randers Tegl is now focussing on the group‘s roof tile plants. After the summer, Randers Tegl‘s Danish roof tile factories will switch to biogas supply, and subsequently the conversion of the energy supply of the group‘s German factory in North Rhine-Westphalia will begin.

„We believe that we can make similarly large reductions in our roof tile products, and this is absolutely necessary to stay ahead of the phasing-in of stricter requirements in the renovation market,“ says Kenneth Moesgaard Poulsen.

Facts: What is GWP

Global Warming Potential (GWP) is a unit of measurement that shows how different materials and processes affect global warming. The GWP value indicates how large the greenhouse effect is compared to the greenhouse effect of emitting 1kg of CO2. The lower the GWP, the less a material contributes to climate change. Randers Tegl‘s GWP values are calculated based on the products‘ production phase (A1 to A3), which covers the extraction of raw materials (A1), transport to manufacturing (A2) and material production (A3).

About Randers Tegl A/S

Randers Tegl is one of Northern Europe‘s largest brick manufacturers and currently has five production units in Denmark and one in Germany. Headquartered in Aalborg, the Randers Tegl Group has 300 employees and an annual turnover of approximately DKK 650 million.

Randers Tegl offers a wide range of facade bricks, roof tiles, paving and lintels, which are produced at five brickworks, four in Denmark and one in Germany. Randers Tegl has sales companies in Sweden, Germany and Norway and generates more than 50 percent of its total sales from exports.