New product series of extrusion devices

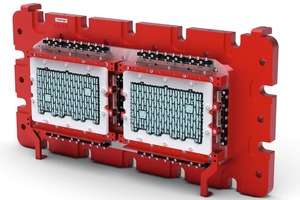

All components of the Omega extrusion die that are in direct contact with the clay are made of anti-abrasion materials, to ensure high, long-lasting quality of external regulation and high resistance to wear. The columns of the core-support-bridge are built with a square section in an NC-controlled process because the anti-abrasion steels used are only available on the market in the form of steel plate. Special attention was also paid to the welding process: the die is only welded where absolutely necessary, and welding is performed exclusively with the TIG welding method, using electrodes made of the same anti-abrasion material.

Also worth mentioning is the use of alternative materials such as aluminium for the production of some components of the extrusion die that have no contact with the extruded clay, with the aim of reducing the weight of the extrusion die for easier transport and handling.

A very important aspect for the customers is that they can obtain a spare part for every component of the extrusion die without having to send the die to the manufacturer.