Optimization of the strength properties of clay masonry bricks

Research project conducted by the Research Alliance of the Clay Brick and Tile Industry Regd. (FGZ)

Project number

AiF 15253 N

Project funded by

BMWi through the German Federation of Industrial Research Associations “Otto von Guericke” Regd. (AiF)

Implemented by

Brick Research Institute Essen Regd. (IZF), ibac Aachen

Project manager

Dipl.-Ing. Michael Ruppik

1 Introduction and objective

A sub-objective of the research project is to improve the strength properties of clay masonry bricks and accordingly the load-bearing capacity of the masonry, especially the shear strength. In this process, the known, important structural-physical properties are not to be significantly changed or adversely affected.

On the one hand, optimization is to be achieved with raw-materials- and production-based measures. On the other hand, based on the development of a realistic material model (material laws) for the numerical simulation of the load-bearing behaviour of masonry built with clay bricks, an optimization of the perforation structure is planned. The starting variables necessary for this (including the fracture behaviour) are to be determined as accurately as possible in small-scale tests.

2 Findings and conclusions

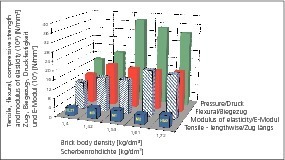

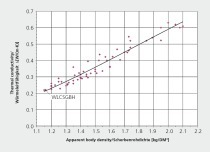

For optimization of the perforation structure, first small specimens are tested and the material laws of brick bodies determined, especially the fracture behaviour. These are implemented in a finite element model and on this basis the masonry bricks are modelled with three-dimensional continuum elements. In comparison with small-scale tests on masonry bricks, for the compressive load, there is a very good agreement between the test result and numerical simulation. In contrast, for the tensile loading, there results a considerable over-estimation of the test results on account of inhomogeneities not considered in the model. With the determined material laws, the perforation pattern geometry of the masonry bricks is optimized based on the numerical analysis of the compressive and tensile load bearing behaviour. »2 shows the starting perforation pattern (left) and the optimized perforation pattern (right).

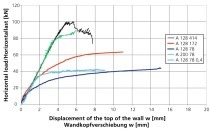

Parallel to the optimization of the perforation geometry, a material-optimized brick is produced in the brick plant. The comparatively higher mechanical loadability of the body determined on laboratory scale is confirmed with original bricks from an optimized mix M3 after testing of the compressive strength in the defined order of magnitude. Following the concluding testing of the compressive and shear load-bearing capacity on storey-high masonry walls, the following can be established: the optimized brick body shows an increased crack tendency in firing, which necessitates additional optimization of the brickmaking process. If this optimization is realized, a discernible influence can be expected in respect of the shear loading capacity of storey-high masonry walls too.