Measures for reducing the influence of moisture on the expansion and contraction behaviour and strength losses of industrially fabricated adobe bricks

BMWi through the Cologne-based Arbeitsgemeinschaft industrieller Forschungsvereinigungen

“Otto von Guericke” e.V. (AiF)Implemented by

Brick and Tile Research Institute Reg’d (IZF)Project managerDr.-Ing. Anne Tretau

1 Background

2 Context and procedure

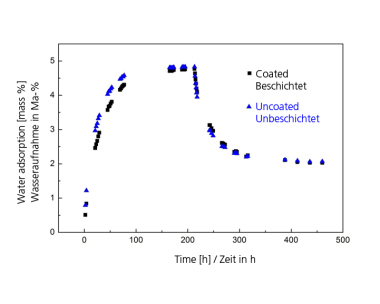

Clays of various type and provenance were tested for suitability in the production of extruded adobe bricks. The extruded specimens were exposed to fluctuating climatic conditions. The specimens were first dried at 105° C, then stored at 20° C and 90% r.h., and again dried and moistened.

3 Findings

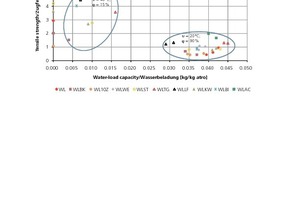

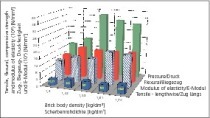

Three of the twelve clays were chosen for further investigation in connection with the fabrication of adobe bricks satisfying modern quality criteria. Various mass fractions of traditional and modern additives were added to the clays, always with preference given to ecologically benign substances, for adobe bricks are used primarily by people with a well-developed ecological awareness. Also, large volume fractions or organic constituents were purposely dispensed with in order to avoid swelling. Typical additives included boiled linseed oil (WLLF), a bituminous emulsion (WLBI), cement (WL10Z) and Acronal (WLAC). The action mechanisms of the individual additives are explained. The modified clays were extruded and subjected to alternating climatic conditions. Most additives were found to increase the dry tensile strength of the specimens, which is determined after drying at 105° C, with the associated water load defined as zero. The maximum gain as achieved by adding 2.5 wt% Acronal (solid). Adding 3 wt% quicklime (WLBK) or 10 wt% cement yielded significantly lower tensile strength levels (»1). However, the loss of strength due to sorption at 20° C and 90% r.h. remained insignificant. Both additives reduced the apparent density and the volumetric water content. The same applies, though to a lesser extent, to clay modifications involving boiled linseed oil and bituminous emulsion, both of which marginally improve the tensile strength as compared to that of the reference body. Moreover, the additives are able to prevent disruption of property drift, i.e., tensile strength remains unaltered after several rounds of moist storage. The same is true of the specimens‘ geometry. Hence, the fabrication of extruded adobe bricks satisfying modern quality criteria is feasible.

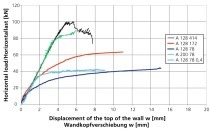

Additionally, the long-term behaviour and water resistance of adobe bricks employed in three test walls was investigated. The results showed that clay modified with cement, Acronal (solid), boiled linseed oil and bituminous emulsion are dimensionally stable. Cement-modified clay bricks become thoroughly soaked but do not crack. Conspicuously, the most water-resistant adobe bricks were those with the smallest <0.1 μm pore fraction. This modification also happens to reduce the specific surface area.