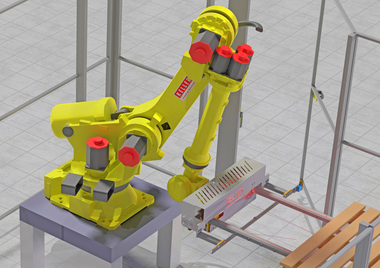

Brick manufacturers switch to circular plastic returnable pallets

The Dutch brick manufacturers who are members of the Koninklijke Nederlandse Bouwkeramiek (KNB) will switch to the use of circular plastic return pallets. In collaboration with Circular Plastics as logistics manager and pallet manufacturer Cabka, a plastic return pallet has been developed. It will replace wooden pallets throughout the entire logistics process from the factory to the construction site, including the return and reuse of the pallets.

Over a period of two years, the design of the pallet was developed and field tests were carried out with 1:1 scale models in various factories. Currently, 4,000 plastic pallets with an experimental mould are being produced for the pilot phase. In the coming months, the pallets will be intensively tested in the laboratory, on the brick manufacturers‘ production lines, during transport to the customer and during use on the construction site.

The following brick manufacturers are now gaining experience with the first production series: Caprice, Engels Baksteen, Rodruza, Steenindustrie Strating, Steenfabriek de Rijswaard, Vandersanden and Wienerberger. In addition, experience with the daily use of the pallets is being gained through trial deliveries to construction sites. The initial reactions to the pallet as part of the mission of a waste-free construction site have been very positive.

All experiences during this test phase, which lasted several months, will be recorded and implemented in a possible optimisation of the design. Based on the final design, production of the plastic return pallets could eventually begin in mid-2025.