Who actually returns your pallets for packaging?

They have to be stacked to a certain height, aligned in the right direction and in a usable condition. What‘s more, there always needs to be enough of them in the packaging line. But what happens when the pallet stack is empty? Production stops. Processes are interrupted to supply the line with new pallets. The staff is actually already involved in production and finding additional staff just for destacking, checking, turning and preparing pallets is usually a challenge.

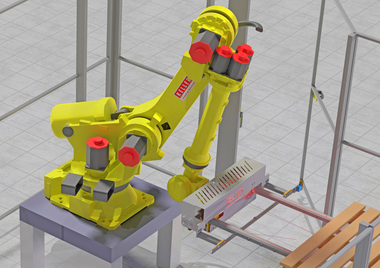

This procedure was also a matter of course for a long-standing customer of the mechanical engineering company Lingl Anlagenbau GmbH from Krumbach, the Engels Steenfabrik in Panningen in the Netherlands. But the Bavarian company proposed a convincing solution to make their customer‘s daily production routine easier. Thus, a pallet-turning robot from Lingl started operating in Panningen at the beginning of March 2023.

In an interview with Dennis Wimmer from Lingl, Ruud Engels, Managing Director at Engels, explains how the cooperation came about and what the new system part means for operational processes.

Ruud Engels: We didn‘t decide on it consciously. It was a recommendation from Lingl that gave us the idea. The part of the system at the packaging with the pallet gripper was old. We knew we had to get a new gripper to reduce machine downtime. Actually, we only wanted to exchange the gripper, but Lingl‘s idea to optimise this part convinced us.

What was the process like before you got the new pallet destacking and staging robot?

RE: The pallets return from the

construction site or are newly

delivered. For transport, these

must always be nested so that

the stack is stable, saves freight

space and is easy to transport. However, this entails that they have to be somehow de-nested or destacked so that they can be fed back into the packaging plant. For this we usually needed temporary workers who repeatedly destacked pallets for a few hours a week so that our forklift driver could feed new stacks of pallets into the packaging plant every half hour.

RE: The main problem in these times is to find staff by the hour for such tasks. We had to interrupt our production again and again. Sometimes production staff had to fill in. It was not easy work and there was no continuity in the process.

RE: Yes, we are very satisfied. The processing of the order on the part of Lingl up to the commissioning went as we had imagined. The robot runs continuously and facilitates our production processes. In the meantime, we have even found out other advantages.

RE: We are now more flexible and no longer need staff to de-nest the pallets. Because the pallets can now be nested at the packaging line, there is room for more pallets and production can run longer without having to feed in new stacks of pallets. The forklift driver no longer has to bring in stacks of pallets every half hour. In addition, with the new robot we can easily nest our different pallet sizes and only have to switch between the programmes. Before, we had to mechanically modify the gripper for the different pallet sizes.

RE: Our entire system has been implemented by Lingl so far and we have always been satisfied with the cooperation and the service of Lingl. It was out of the question for us to ask another supplier for this partial plant.

Mr Engels, thank you for your time and the interview.

The interview was conducted by Dennis Wimmer from Lingl.