Separating brick particles from the sand fraction in construction and demolition waste based on their magnetic susceptibility

In the processing of construction waste, sorting the delivered material mixes is one of the key process steps for the production of reusable recyclates. In the fine particle range, there is a lack of processes suitable for this purpose. A process that has not yet been investigated is the separation of concrete-mortar-brick mixes on the basis of susceptibility. Starting from susceptibility measurements, sorting tests were conducted with a rare earth roll magnetic separator. The positive results of the tests described here are set to be the starting point for further tests on the efficiency of this sorting method, which has so far not been applied in the processing of construction waste.

1 Sorting methods for processing construction and demolition waste

In the processing of construction and demolition waste, sorting of the delivered material mixes is one of the key process steps for the production of recyclates with defined properties. On the one hand, established methods like air or jig separation are used. These processes are based essentially on differences in density. On the other hand, manual sorting is also still employed. In some cases, instead of these methods, sensor-assisted processes have already been implemented. Sorting by means of “intelligent grippers” in combination with an AI-assisted detection algorithm is so far unique [1]. With the above-mentioned techniques, mineral particles with sizes in the centimetre range can be sorted. Far fewer processes are available for sorting sands. Specialist sand jigs, aquamators and spiral separators are possible wet processes that are suitable for particle sizes in the sand range. The separation criterion here is density. Various types of material with only very slight differences in their density cannot be separated. Sorting based on magnetic properties is on the other hand state of the art for ferromagnetic constituents in construction waste. Armouring irons and small iron components are removed with overbelt magnetic separators and/or drum magnetic separators.

The deficits in the available sorting techniques impact the recycling level. For unsorted masonry rubble, there are hardly possibilities for reuse so far, so that it is often landfilled or used for backfilling. Exception is the use as raw material for the production of lightweight aggregate like expanded clay as described in [2]. The brick sands sorted from the masonry rubble can, on the other hand, be used in vegetation technology. They can, however, also be used in the sense of recycling raw material as a partial raw material replacement for reuse in the production of bricks. Two different processes have already been realized or in the early stage of realization [3]:

The production of cement-bonded bricks from recycled materials without further thermal processes

The production of thermally bonded bricks that are shaped by means of uniaxial pressing as in technical ceramics.

In the production of cement, pure brick sands can be ground and then used as “additional cementitious materials” and consequently contribute to the reduction of the consumption of cement clinker and the lowering of CO2 emissions [4], [5], [6].

2 “High-intensity” magnetic separation of primary and secondary resources

When materials are exposed to a magnetic field, they are magnetized. Depending on the reaction of the material to the magnetic field, three types of magnetism can be differentiated:

Ferromagnetism: In the case of ferromagnetic materials, magnetization is oriented towards the external magnetic field and is particularly strong on account of the specific reciprocal effect. As a result, a ferromagnetic material is strongly attracted by magnets.

Paramagnetism: In the case of paramagnetic bodies, magnetization is oriented in the same direction as the external magnetic field, however, without the above-mentioned amplifying reciprocal effect. A paramagnetic material is therefore only very weakly attracted to magnets.

Diamagnetism: The magnetization is opposite to that of the external field so that a diamagnetic material is weakly repelled.

Ferromagnetism is the longest known and used form of magnetism. With the development of rare earth magnets, paramagnetism has also become usable. The strength of the magnetization M is coupled with the magnetic field strength H based on the relative permeability µR or the susceptibility χ:

M = (µR-1)*H = χ*H

Information on the susceptibility of elements and inorganic compounds can be found, for example, in [7] to [10]. The specifications differ considerably in some cases. »Table 1 summarizes several susceptibilities from [7] for compounds that are relevant for the construction materials sector.

In the processing of primary resources, the development of “rare earth magnets” with high field strengths from around the 1980s opened up new possibilities for sorting. With this, sorting on the basis of paramagnetic properties can be conducted. On account of their good performance and low operating costs, RER separators have found wide acceptance in the preparation of coal and industrial minerals. Following applications are listed in [7] and [11]: processing of bituminous or sub-bituminous coal, lignite, lignite fly ash, feldspar, ilmenite, manganese, bauxite, perlite, colemanite, nepheline syenite, silica sand, wollastonite and diamond.

In the processing of sands for glass production, sorting by means of RER separators can be used for the separation of Fe2O3-containing minerals [12], [13]. With a three-stage sorting plant with a maximum field strength of 0.73 tesla, the Fe2O3 content of 5.2 mass% in the feed material can be reduced to 0.23 mass% in the product.

The use of RER separators can also offer advantages in the production of crushed sands for the production of mortar and concrete. The content of mica, which can have an unfavourable effect on the concrete properties and which after processing of gneiss was present as free particles in the fraction < 2.36 mm could be reduced considerably [14].

In the sorting of crushed sands that can be produced in the processing of used concrete, particles with a high content of cement paste could be separated from those that consisted of quartz and feldspar [15]. The separation of concrete fines with a high-intensity permanent magnetic sorter with 1 tesla magnetic field strength was tested for the fractions 125 – 250 µm, 250 – 500 µm and 500 – 1 000 µm [16]. The yield of the non-magnetic fraction, i.e. the sand fraction, increased from 62.5 mass% for the finest fraction to 89.3 mass% for the coarsest fraction. The non-magnetic fractions of all size classes contained a lower content of cement paste totalling 3 – 11 mass%.

For the processing of construction and demolition waste as a mix of concrete and bricks, RER separators have not yet been used. First information from the literature on the distinguishability of brick and concrete sands on the bases of magnetic properties was already available back in 2004 [17], [18]. With an isodynamic Frantz-Separator, brick particles were separated from cement mortar particles on the basis of their Fe2O3 content, which was < 1.25 mass% in mortar and 3 to 4 mass% in the bricks. Despite these positive results, this possibility was no longer pursued or no more was reported on it.

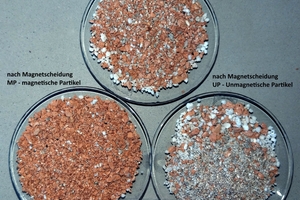

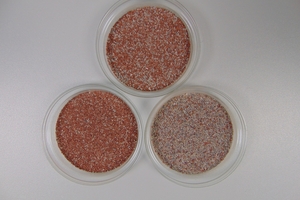

Our own first tests with the help of a RER separator confirmed this result. A feed material consisting of brick, concrete and mortar particles in sizes < 4 mm could be separated into a “red” high-brick and a “grey” high-mortar fraction (»Figure 1). This result was the starting point to further pursue the potential of this sorting method.

3 Measurements of the susceptibility of concrete and mortar samples

For the tests conducted here, various concretes and bricks as well as concrete and brick recyclates were used. The particle sizes of the tested samples ranged from 0.063 to 2.8 mm. For the characterization of the starting materials, their chemical composition was measured by means of X-ray fluorescence analysis of fused tablets (»Table 2).

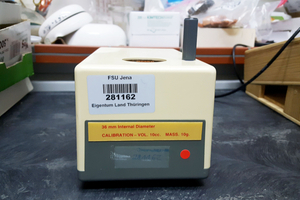

The magnetic susceptibility as the key parameter of the RER sorting was determined with two different methods. The measurement of the mass-specific magnetic susceptibility was determined with the combination of measurement instrument and sensor shown in »Fig. 2. The powder samples were filled into 12.5-ml boxes made of transparent polystyrene with a polyethylene lid and then measured.

For the measurement of the volume-specific susceptibility with the Bartington E-sensor, the samples were left in their original plastic bags and the sensor laid on top. The powder was pressed slightly with the underside of the sensor to obtain a level surface.

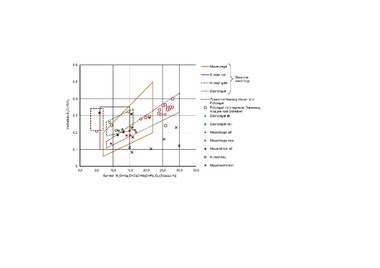

The summary of the measured values in »Table 3 shows that there are significant differences between the susceptibilities depending on the type of the material. The cement stone and the concrete produced with limestone aggregate have the lowest mass-specific susceptibilities < 100 x 10-9m3/kg. The susceptibilities of the concretes with high-quartz aggregates remain well below 1 250 x 10-9m3/kg. Only for one concrete was a higher value measured, which can be attributed to the colouring of the concrete. In contrast to this, the susceptibilities of the ceramic-bonded construction materials were all over 1 000 x 10-9m3/kg and mostly even over 2 000 x 10-9m3/kg. Accordingly, apart from a few exceptions, a distinguishability is given.

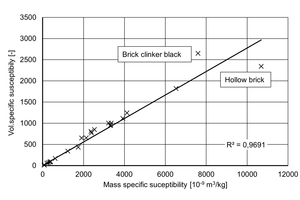

The comparison of the susceptibilities measured with the various sensors shows that the two measured values correlate well with each other (»Fig. 3). Deviations are only detected for two of the total of 23 pairs of values.

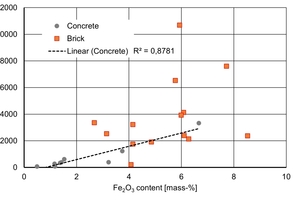

The dependence between the Fe2O3 content and the mass-specific susceptibility shows clear differences for the two material groups, concrete and bricks, under consideration (»Fig. 4). For the concretes, there is a clear correlation between the Fe2O3 content and the susceptibility. For bricks, apart from a few exceptions, higher values are always measured than for the concretes. Such a clear dependence on the Fe2O3 concrete, however, was not observed. The reason for these differences is that the iron oxide contained in the brick can be present in various oxidation stages that can differ in their magnetic properties.

4 Tests on the separation of brick and concrete sands with a rare earth magnetic separator

4.1 Magnetic separator used

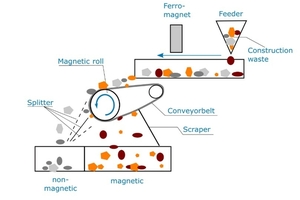

The tests were conducted with a rare earth overbelt magnetic separator, the field strength of which was 2.1 tesla according to the manufacturer’s specifications. »Fig. 5 shows a schematic of the separator and the model used for the tests. The most important components of the device are the belt conveyor, the magnet installed in the head roll and the “splitter”.

A vibrofeeder is used to feed the material onto the belt conveyor with a width measuring 300 mm. Above this is an overbelt magnet, which removes the ferromagnetic components contained in the feed material. The field strength of 2.1 tesla of the magnet installed in the head roll is reduced as a function of the thickness of the belt conveyor so that the effective field strength for the belt thickness used here is around 1.4 tesla. As a result, the paramagnetic particles remain stuck to the head roll whereas the non-magnetic particles are ejected. The “splitter” supports the separation. For the rare earth magnet separator used, the speed of the vibrofeeder, the belt speed and the position and inclination of the splitter can be varied.

4.2 Samples used

The following samples were selected for the sorter tests:

C 2 (concrete with limestone aggregate, C 3 (concrete slab) C 8 (paver)

B 3 (old brick), B 6 (hollow brick), B 9 (clinker, black), B 10 (split brick, buff), B 12 (sewer brick), B 14 recycled brick material.

All starting materials were comminuted to a particle size < 2.8 mm and screened into the fractions 0.063/0.5 mm, 0.5/1.0 mm and 1.0/2.8 mm. The concrete and brick samples were mixed in the mass ratio of 1:1. For every separation test, a quantity of 800 g of the dried, sized, mixed samples was used and placed into the feed hopper of the sorter. From there, the material was transported on the vibrofeeder to the feed belt of the magnetic drum. As the material passed the magnetic drum, it was separated into “magnetic” and “non-magnetic” particles. The resulting products were collected and weighed. A total of 193 sorting tests was conducted.

4.3 Methods for evaluation of the sorting results

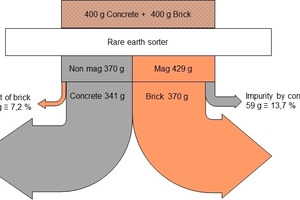

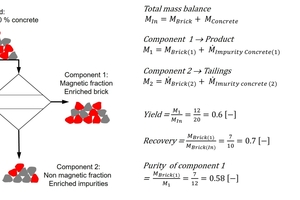

The overall balance of the sorting process in »Fig. 6 shows the division of the starting mass flow of equal proportions of concrete and bricks into the main mass flow sticking to the magnet and the ejected mass flow. The former consists mainly of bricks and contains concrete residue as impurities. The ejected mass flow consists almost exclusively of concrete. The following overall mass balance applies:

mconcret in + mbrick in = mnon mag out + mmag out

The loss in the sorting depends on the treated fraction. It totals 0.73 mass% for the fraction 0.063/0.5 mm, 0.18 mass% for the fraction 0.5/1 mm and 0.33 mass% for the fraction 1.0/2.8 mm.

The total mass balance is determined by means of weighing. It indicates how much of the material feed goes into the magnetic product. It does not, however, provide any information on the quality of the product. To obtain details on that, the brick content in the magnetic fraction must be determined. This can be done based on the colour (»Fig. 7).

At the time the tests were performed, however, no suitable hard- and software solution was available for test evaluation based on colour. For this reason, the systematic differences that exist between the losses on ignition of the concretes and of the bricks (»Table 1) were used for assessment of the separation efficiency. For this purpose, the masses of the formed magnetic and non-magnetic fractions as well as the losses on ignition of the starting materials and the sorted products were measured. From the total mass of the magnetic particles and the loss on ignition mass balance for these particles results the mass of the bricks in the magnetic fraction:

mmag = mbrick mag + mconcrete mag

mmag*LOImag = mbrick mag*LOIbrick + mconcrete mag*LOIconcrete

mbrickmag = mmag*(LOIconcrete – LOImag)/ (LOIconcrete – LOI brick)

4.4 Results of the magnetic sorting

With the sorting process, the input material is split into a magnetic fraction with a higher brick content than in the feed material and a non-magnetic fraction with the concentrated “residue”, i.e. concrete. From the mass balance, the yield, the recovery and the purity of the magnetic fraction were calculated. Goal of the sorting is to produce a brick fraction with maximized purity. The degree of purity is therefore the most important index.

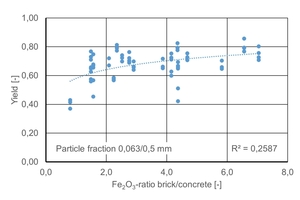

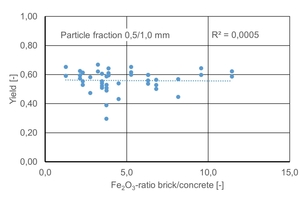

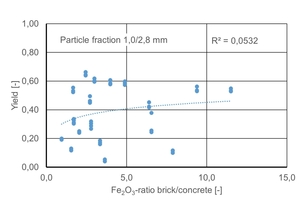

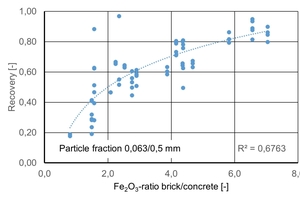

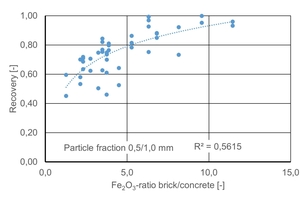

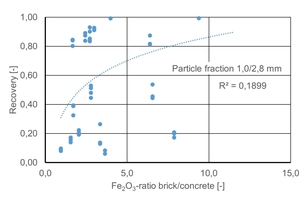

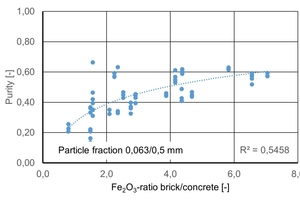

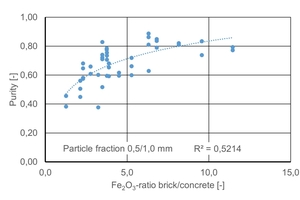

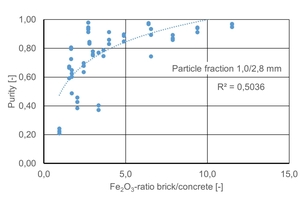

For all tested brick-concrete combinations, the influences of the Fe2O3-ratio of brick-concrete on the yield of the magnetically separated fraction as well as on the brick content of this fraction were determined. A differentiation was made between the particle size fractions 0.063/0.5 mm, 0.5/1.0 mm and 1.0/2.8 mm.

The yield of the magnetic fraction lies between 0.7 for the finest and 0.4 for the coarsest fraction (»Fig. 9). The theoretical yield for a separation into the pure constituents would have to be 0.5. The higher value in the finest fraction can be attributed to the “foreign concrete constituents”. The lower value in the coarsest fraction can be attributed to the incorrect discharge of brick particles in the non-magnetic fraction. The ratio of the Fe2O3 quotients of brick to concrete has no definite influence. The yield increases considerably with rising Fe2O3 ratio between brick and concrete (»Fig. 10). For the coarsest fraction, there is no definite dependence. The brick content in the magnetic fraction increases in all three tested fractions with rising Fe2O3 ratio (»Fig. 11). In the 0.5/1.0-mm fraction, Fe2O3-ratios over 8 lead to brick contents over 80 mass% in the magnetic fraction. In the fraction 1.0/2.8 mm, this limit is already reached for Fe2O3 ratios of 4.

Yield and purity therefore show opposite trends in terms of their behaviour. In the fine fraction, a yield > 0.5 is achieved at the cost of low product purity. In the coarse fraction, the yield is lower, but in the magnetic fraction, high brick contents are reached.

With the separator used, it was possible to vary the following machine parameters

Roll speed

Position of the splitter

Thickness of the conveyor belt.

These parameters have only a minor influence on the sorting efficiency. Even a double sorting of the material did not lead to a significant increase in the brick content of the magnetic fraction.

As material parameters, the influence of the width of the fraction to be sorted and the material moisture content were investigated. A positive influence of the drying of the material on the sorting performance could not be established.

5 Summary and conclusions

Mineral construction waste are often mixes of various construction materials. If type-appropriate recycling is to be achieved, sorting based on the type of construction materials must be performed. In the coarse size range, traditional solutions like jigging machines as well as new processes on the basis of the identification of certain construction materials based on their spectral properties are available. In the fine grain range, these methods cannot be applied. The focus of the investigations described here was the question whether construction waste can be sorted based on its magnetic susceptibility.

In the first part, the susceptibility of brick and concrete grain sizes were measured, for which no values could be found in the literature. For the nine tested concrete samples, the susceptibility increased in a linear function with their rising Fe2O3 content. With one exception – one concrete from a coloured paver – it stayed under 1 200*10-9 m³/kg. For the 15 brick samples – also with one exception – values over 1 900 m³/kg were measured across the board. As a result of the different oxidation stages of the iron oxides in the brick, the values are scattered over a certain range.

For the sorting tests, a belt sorter with a rare earth magnet in the head roll was used. The field strength of the magnet was 1.4 tesla. Concrete and brick samples were used, which were first comminuted, then sized and finally mixed in the ratio of 1:1. The content of concrete and brick after the sorting were determined on the basis of the losses on ignition, which differ considerably for the two materials.

The results of the investigations show that a separation between the brick particles with higher susceptibility and the concrete particles with a much lower susceptibility is possible. The tested machine parameters, like the speed of the head roll or the splitter setting, have only a minor influence on the sorting performance. Repeated sorting of the magnetic material did not lead to any significant increase in the brick content.

The positive results of the tests described here justify a further investigation of this sorting method. Reasons also include the low equipment costs of this method and the fact that for the first time a practicable process for sorting construction rubble < 4 mm would be available. A focus of further tests must be to find a practicable, but simultaneously sufficiently accurate method for determination of the brick and concrete content in the two recovered products. Moreover, other types of construction material should also be included in the investigations.

Acknowledgement

The investigations were conducted as part of the programme “FuE-Förderung für gemeinnützige externe Industrieforschungseinrichtungen – Innovationskompetenz” (R&D Support for Non-Profit External Industrial Research Institutes – Innovation Capability) of Germany’s Federal Ministry for Economic Affairs and Energy under the project sponsorship of EuroNorm Gesellschaft für Qualitätssicherung und Innovationsmanagement mbH.

The susceptibility measurements were conducted by private lecturer Dr Bernd Michael Pirrung from the Institute of Geosciences at Friedrich-Schiller University of Jena, for which we should like to express our sincere thanks.