ceramitec 2015: Raw materials and recycling increasingly gain in importance for the refractories sector

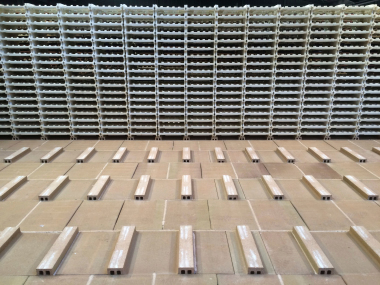

ceramitec 2015 offers refractory manufacturers the opportunity for exchanges with suppliers from the mechanical engineering and kiln construction sectors and for meeting with raw material suppliers and recycling specialists with a global market presence. In turn, refractory suppliers will present their concepts in Hall A2.

The European refractories industry has a share of 10 % in the world market and employs some 20000 people. It sells 40 % of its products outside the European Union and thus underlines its global network and importance.

The steel industry alone consumes some 70 % of the refractories. Consolidation in the worldwide steel market and the associated concentration of the purchasing power have exerted increasing pressure on the refractories industry in the past years.

Consequently, the refractories industry is continually working on innovations for materials, processing methods and refractory construction. In doing so, the topic of raw materials is constantly in the focus as it decisively influences product quality and competitiveness. Moreover, it accounts for the lion's share in the manufacturing costs - in respect of both formed and unformed masses. In the past years, the specific raw material consumption could be steadily reduced for the different user segments thanks to continuous, practice-oriented research work.

In the leading industrialized countries, the refractories industry gives top priority to energy and material efficiency in all production steps. Key issues are the availability and longevity of the installed systems, continuous supervision of the production processes and reliable product quality.

Since it is becoming ever more difficult to dispose of refractories in landfills once they are no longer in use, the topic of recycling is more important than ever. Also new EU rules urge that this type of waste be recycled. Although regenerated refractories are pre-reacted products, their treatment is cost-intensive because impurities require thorough removal in order to ensure recyclability. Thus, they are no favorable alternative to virgin material.

Refractories are hidden champions in their user industries. Nevertheless, refractory manufacturers continue demonstrating their high innovation potential. Meanwhile, they have developed to become system suppliers – on the one hand with respect to the raw materials and on the other hand with a view to the optimization of the production technologies.

Messe München GmbH

www.ceramitec.de