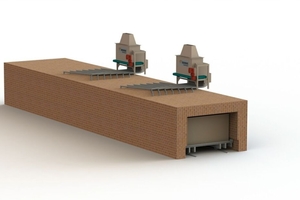

Ceric Technologies offers solutions and services for the production of heavy clay building materials

Ceric has always been a major player in the development of heavy clay technology. It develops and controls all necessary process steps:

» Raw material preparation and product shaping

» Thermal industrial processes: dryers, kilns, burners

» Process control and supervision

» Handling, automation and robotics

» Production data management

Since its creation, Ceric has designed and commissioned around 500 heavy clay plants around the world. Ceric has a long tradition of innovation and technological leadership. Systematic research, tests and cooperation with customers lead to optimized processes and innovative products perfectly adapted to customers’ needs. Individual solutions that also contribute to sustainable development and environmental protection ensure customer satisfaction and sustainability. Ceric’s core business is to provide solutions to:

» Reduce energy consumption

» Improve process and process stability

» Optimize production capacities

» Reduce and simplify maintenance

» Improve and simplify the man-machine interface

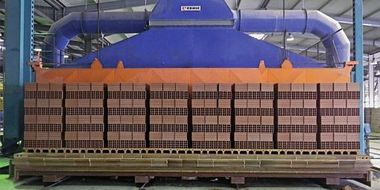

An innovative approach following the Ceric tradition is the use of biomass for firing heavy clay products. The Ceric biomass firing system enables the use of solid fuel such as sawdust, rice husk or other sources of biomass with a particle size up to 5 mm. The system enables firing process that is just as safe and controlled as gas firing, but without the carbon footprint of fossil fuels.

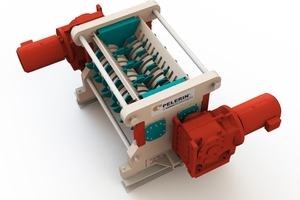

Ceric also continuously optimizes its range of clay preparation machines. Ceric’s latest roller crusher, the first machine of the Ceres range, has been completely reworked and now boasts several new features. The Ceres new range of roller crushers incorporates Ceric’s core values: performance, ruggedness, reliability, and easy maintenance. This roller crusher meets clients’ maintenance needs and follows their markets’ trend. Early in the design stage, Ceric wanted the Ceres roller crusher to be compact in order to offer the crusher for both equipment renewals in existing plants and new factories. It also includes two independent geared motors (supplied by Ceric’s partner SEW Eurodrive) for the roller drive and is available with multiple options:

» To meet process requirements (sticky clay, frozen, etc.) Ceres may be equipped with different geometry blades

» Optional frequency converter for the roller drive for finer comminution of the clay clots, especially when handling wet clay

» Ceres may be equipped with clod tiller shaft to enable the comminution of wet or frozen clay

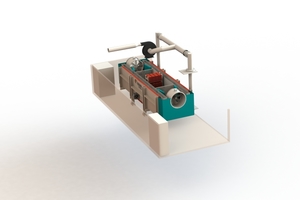

Ceric is offering its new mobile drying test cell to heavy clay operators in order to work closely with them on their own process to improve quality and yield. Tests performed on site allow Ceric to offer the optimum drying solution for each project.

Ceric also offers training services to operators, which cover product development, mix formulation and performance improvement.

Ceric Technologies

www.ceric.com