State-of-the-art materials handling technology by VHV Anlagenbau enables maximum flexibility at Röben’s new clinker brick plant in Bannberscheid

With the opening of

their newly modernized clinker brick plant in Bannberscheid in February 2009, Röben Tonbaustoffe GmbH established itself as a specialist for customer-centred special objectives in the ceramic market place. The plant has three production lines – one each for ceramic clinkers, strip tiles and pavers – all fed with high-quality raw materials from Westerwald. It took a complex materials handling system to provide all the requisite multifunctional support for the plant’s product array in terms of finishes, colours and dimensions.

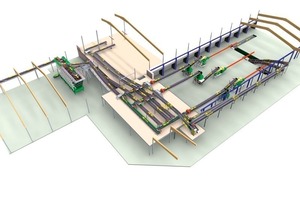

After convincing Röben’s management with a set of three-dimensional plans, this materials-handling challenge was taken up by VHV Anlagenbau GmbH. The facility was designed for arbitrary distribution of material from two sump-house basins to the three extrusion lines. There is also a 200-ton box feeder serving as a flexible standby clay store for running small batches independently of the routine sump-house material supply. The box feeder can be filled with prepared, ready-to-process clay body from any souring basin, either directly from the sump houses or truckload by truckload.

All systems are designed to enable material infeed from any bin to any extrusion line whenever there is a change of composition. Each extruder has its own upstream circular screen feeder for bridging switchover times and reintroducing scraps from any of the cutters. Recycled extrusion scrap is returned via the same metal-detector-equipped supply line that feeds in the appropriate fresh material.

In all, it took 39 belt conveyor systems to achieve the targeted product diversity and short retooling times for different formats, finishes and colours. Most of the conveyors are arranged on a distributing platform above the temporary storage distribution tracks for kiln cars. To ensure optimal accessibility, the platform has room underneath for operating forklifts or mobile cranes.

Röben Tonbaustoffe GmbH is now in a position to deliver – with ease – a wide variety of products on the shortest of notice. On March 28, while a VHV delegation was touring the plant, works managers Mr Andernach and Mr Daun noted: “Time and again, we see how very beneficial it is to have all these numerous alternatives at our disposal, and we take frequent advantage of the resultant flexibility.”

In addition to all the new materials handling gear, the plant’s existing buildings were also fitted out with new shaping, drying, firing and setting equipment. With this investment, Röben has accommodated the plant’s capacities to current market requirements, hence setting the stage for further decades of successful production activities in Westerwald.