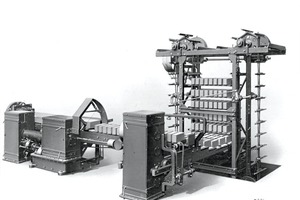

100th anniversary of the Keller fully automatic brick handling machine “Type Hörstel“

Thus the fully automatic brick handling machine “Type Hörstel“ was the beginning of automatic brick handling and it was no longer necessary to take up each brick and to transfer it manually. The carrying laths (pallets) were introduced into the automatic machine first via an inclined feeding system and later laterally, and a sophisticated mechanism grouped the cut bricks smoothly, separated them and transferred them to pallets. Some time later followed the development of an automatic pallet circulation system with dryer loading and unloading facilities. At the beginning of the 1960s kiln car loading and unloading systems with setting installations and dehacking and packing machines were developed, thus guaranteeing automatic operation from the clay pit to the packing station.

The engineer Joseph Keller, the son of Carl Keller senior, (who as inventor of the dryer finger car in 1894 was already a “revolutionary in brick drying“ and founder of the company C. Keller & Co.), designed several technical and technological novelties for cutting, handling and process engineering installations in addition to the “anniversary fully automatic brick handling machine“.

With their inventive talent and entrepreneurial spirit, the “Keller pioneers“ had already discovered basic elements for an automatic brick production at an early stage. This engineering tradition of developing innovative machines and plants has been continued by Keller HCW ever since. For some years robots have perfected the automatic processes in certain areas of brick, roof tile and ceramic tile factories. Innovative brick factories, such as the Heluz plant in Hevlin (Czech Republic) or Röben in Bannberscheid (Germany) are examples of these engineering skills. You will find further information on this topic on www.zi-online.de (Special “Robot handling”).

Josef Knappmeier