Keller engineers fully automatic unloading and packaging system for Corobrik

With its roots dating back to 1902, Corobrik has become the market leader, above all because of its high quality standard. This quality standard is not only realized by the excellently trained employees, but thanks to the quality of the production facilities.

With the engineering of a fully automatic unloading system, Keller could again prove the quality of its plants at the largest production site with 90 mill. SBE. This had been built by Keller back in the early 1980s.

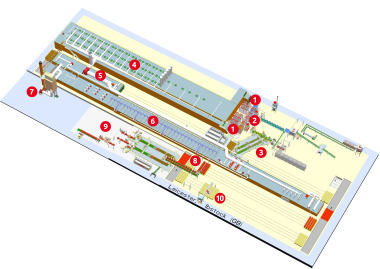

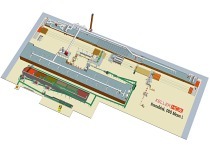

Fully automatic unloading system

The fully automatic unloading system starts with the unloading of packs from the kiln car. The packs are then de-stacked in layers by industrial robots and divided into individual rows.

After manual sorting, the bricks are formed to packs without pallets and are strapped vertically and horizontally.

This important project for Corobrik and Keller, combined with the professional cooperation of all partners, was a complete success. Not only the required plant capacity was achieved, the quality of the dispatch packs could be improved, which has a positive effect, especially on longer journeys to the end-customer.

Keller HCW GmbH

www.keller.de