Freymatic increases setting machine capacity

The Swiss company Freymatic, known across the industry for its innovative and reliable cutter systems, supports its customers with tailored solutions, including the optimization of existing manufacturing processes. These include production automation and process revision to achieve more efficient workflows. Freymatic provides customer-oriented, technically feasible solutions, with consideration for the specific conditions.

One example is the project for the traditional company of Rapis Ziegel based in Schwabmuenchen, Germany. Rapis was faced with the problem that the capacity of the setting machine for narrow sizes, like the 115 interior wall brick, was no longer sufficient. For an increase in the setting rate, two rows of bricks have to be laid on top of each other, after they have been compacted and aligned, and that before programming and in extremely confined space.

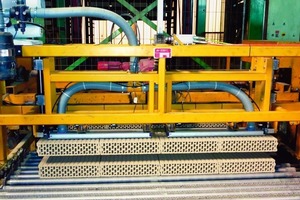

Freymatic has installed compaction with a pneumatically operated double-pusher working in opposite directions for two rows of bricks just upstream of the pallet unloading on the dry side. The brick row doubler stands above the brick row cross conveyor after pallet unloading and immediately in front of the counting barrier. With large-area vacuum suction line, it lifts the first row of bricks and places them gently on the next row. Despite the structured brick surface and gaps between the bricks, the suction box holds the bricks reliably and gently. These specially made elements were designed to be so technically simple that they could be independently installed and commissioned by the customer. The rate increase expected by the customer could be fulfilled with “tailored and timely solution, without any problems”.