Beralmar equips Algerian brickworks

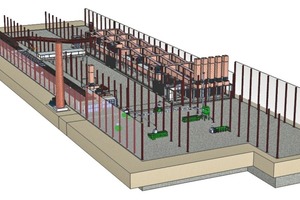

Beralmar supplies different types of dryer, which can be adapted to the specific raw materials and the products made from these. In addition, Beralmar’s range also includes tunnel kilns, automatic control systems for drying and firing processes as well as handling systems.

Projects in Algeria

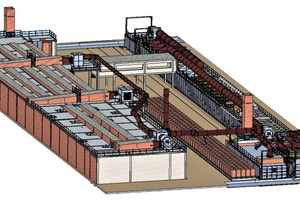

Another example is the second brickworks of Timadanine in Adrar. Here Beralmar was contracted to install a new production line for the production of 327 000 t/year hollow bricks and ceiling blocks.

In both facilities, the clay is prepared in a semi-wet process and dried in a semi-continuous “Mestral” dryer, with a drying cycle of 41 and 25 hours respectively.

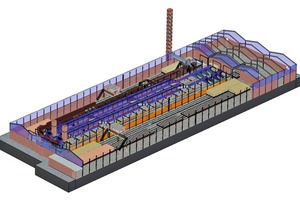

The second production plant supplied by Beralmar for Briqueterie Rym in Annaba is already running at full capacity and produces 262 080 t/year hollow bricks, separation bricks, perforated bricks and brick supports. For this brickworks, the products are loaded into cars and dried in a “Llevant” dryer with a drying cycle of 41.58 hours. All units are equipped with state-of-the-art technology, the equipment for the drying and firing process being adapted by the Beralmar technicians to the specific properties of the clays used.

At all three plants, the products are fired in a pre-kiln and a “Presthermic” tunnel kiln, which can be also operated under pressure, to obtain an excellent quality and reduced energy consumption. They incorporate the proven Beralmar burners (high speed, pulse). The three facilities are equipped with the latest technology necessary for cutting, loading and unloading, setting and palletizing. The plants are supported by the remote assistance service, so that Beralmar technicians, given client authorization, can access the system via the Internet and quickly resolve any problems without the need to travel to the plant.