CSIS inspection system for checking clay columns

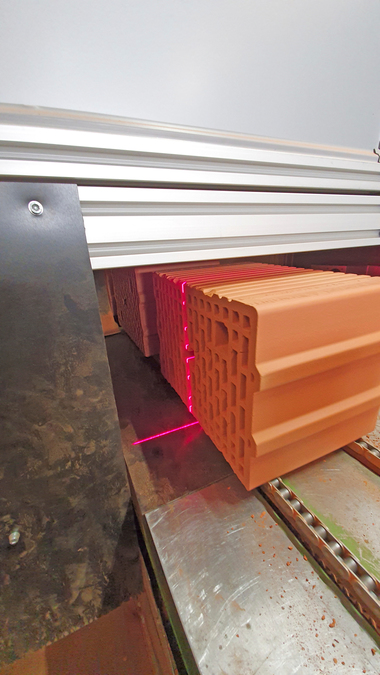

The clay column steadily exiting the extruder generally has a smooth surface. Depending on what surface effects are required, in the next step the column can be further processed, e.g. peeled, scarred, sanded, etc. Then, the ibea inspection system uses three colour matrix cameras to inspect the column and detect any defects. Only then is the continuous column cut into the required green products. If defects are detected, the rejected clay can be recirculated, and losses minimized.

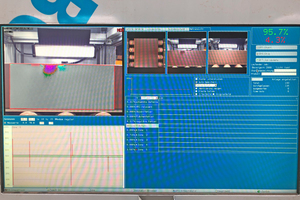

The CSIS inspection system uses three ultrafast colour matrix cameras to inspect the clay column from three sides. Alternatively, a fourth camera can be added to monitor the column from below. With this system, deviations can be detected, monitored and immediately displayed to the plant operative.

The system can stop the cutting process and prevent any unsatisfactorily extruded material going on to the downstream production process. This saves material and ensures that production can continue running without stoppages.

The system can be trained automatically with different product sizes and surfaces.

ibea GmbH

www.ibea.de