“Ceric is back” – on the German market too!

Ceric’s strength lies not just in its ability to engineer turnkey plants, but also in supporting these units in their further development in line with customer requirements. That is Ceric’s commitment to the production plant does not end with its handover: the French plant engineering company has the personnel and technological resources to adapt production lines or plants to meet new needs, to modernize these or to integrate new technologies. Modernization or modification of production lines generally entails lower cost than a newbuild, but calls for comprehensive expertise and know-how, which the Ceric engineers certainly have. Accordingly, Ceric can also meet the needs of the German market and its customers, who are known for their high standards and reputed to constantly challenge the innovative capacity of their suppliers. At Ceric, the focus is on the customer. Cooperation with the German company Gima, an expert on ceramic building materials, is a good example of how Ceric supports a production plant during its entire lifecycle.

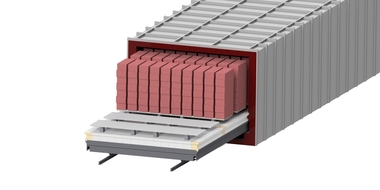

Girnghuber GmbH, the company better known as Gima and based in Lower Bavaria in Southern Germany, has a long tradition in the production of heavy clay building materials. At the facility in Marklkofen, which has been owned by the Girnghuber family since 1903, around 250 employees produce a wide range of clay brick products. Ceric Technologies is very well acquainted with this production unit, as it has already supplied three Hydro-Casing kilns there. Gima contracted Ceric Technologies to increase the number of kiln cars for the Hydro-Casing brick-firing kilns built in 1999. At the end of 2012, a total of 25 additional cars were completed. This contract was associated with several challenges:

› an extremely tight schedule for completion

› completion of the work without adversely affecting the production operation

› use of a new car lining developed by Ceric to optimize the energy efficiency of the cars

The engineers and technicians of the Heat Treatment department at Ceric have demonstrated under the direction of Alexandre Brief exemplary organization and control. Not only have all contractual obligations agreed with the customer been met, all safety regulations have been complied with too. Cooperation with the Gima production team was excellent.

Car structure

Chassis

The complete realization and preassembly of the chassis at the Ceric workshops enabled smooth final assembly on site. The chassis were delivered in two parts to prevent any danger of deformation during road transport. The side plates of the cars consist of two parts to compensate for the mechanical stresses between the upper and lower sections. These stresses are caused by the temperature gradient to which the car is exposed as a result of the repeated temperature increases and decreases.

Lining

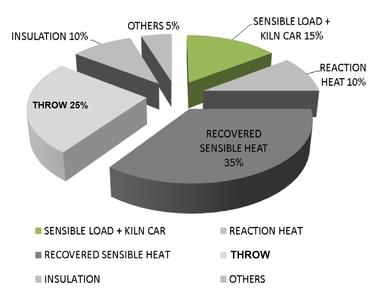

The Research and Development department at Ceric Technologies has developed a new lining in which the traditionally used fibres are replaced with Cerilite L01, an insulation material on the basis of an extremely lightweight, refractory material. For this new lining, the latest ceramic processes are employed and lightweight, resistant and insulating materials used as soon as possible, which were developed together with Burton, a company specializing in the development and production of refractory materials. Cerilite L01 is a material produced on granulate basis, which can withstand temperatures of 1 400° C and introduced into the cars in bulk solid form. Key characteristics of this innovative alternative to what are currently described as “green” ceramic fibres are:

› Energy saving: Cerilite L01 combines increased porosity and low weight, therefore contributing to the desired energy saving and low heat transfer

› Improved insulation thanks to the low thermal conductivity of Cerilite L01

› Lightweight and fast installation/handling thanks to the low weight and bulk solids form (big bag), even in confined spaces, a faster installation time as well as simplified repairs, as the product can be simply vacuumed up and reused

› No health risks: it does not contain any ceramic or silica fibres so that the initial use and future maintenance work are completely without risk

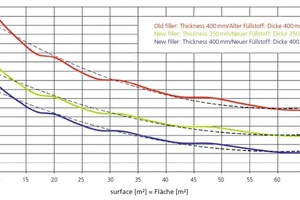

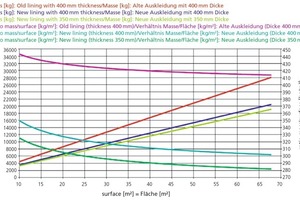

A new design of the chassis reinforcements enables the direct installation of the insulating part of the lining on plates with a flat base. Accordingly, no compact concrete is necessary, which has a negative effect on the energy balance. The new insulation reduces the average loss along the length of the car by 13 to 15% at a temperature of 1 050° C. This energy saving increases with the temperature.