Eco-energetical optimization of drying processes through integration of heat pumps

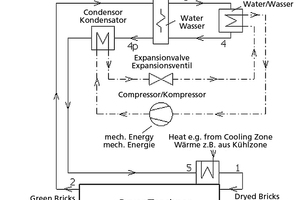

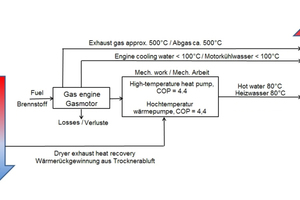

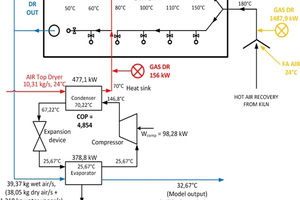

By way of examples, this contribution illustrates how the integration of heat pumps and the recovery of latent heat can enable the economically viable energetical optimization of drying processes, even when kiln and dryer are energetically decoupled.

1 Introduction

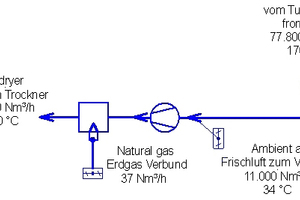

At a heavy clay plant with a daily output of 200 to 400 tons of fired products, the customary use of approx. 20 mass% batching water means that between 40 and 80 t of water per day has to be expelled and evaporated. Accepting that the normal drying energy requirement exceeds 4 000 kJ/kgH2O, the process therefore consumes between 4 000 and 8 000 Nm³ of natural gas every day.

Different types of drying systems, i.e., with continuous-flow or chamber dryers, also vary in terms of how they are integrated into the plant‘s material flow. Their energy supply mode, however, is essentially...