Experience meets innovation

On September 26, some 80 customers from 20 different countries enjoyed a plentiful program and a good opportunity to gather information about Händle‘s latest production-process optimizations, product developments and innovations, system solutions and the expanded applications laboratory in Mühl-acker.

„Putting together what belongs together“

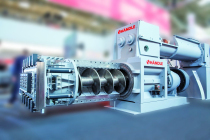

In his welcoming address, Händle‘s Managing Director Gerhard Fischer presented the company and its new subsidiary ZMB Braun as leaders and technological forerunners in numerous areas of preparation and shaping technology – for more than 140 years now. A well-functioning strategy coupled with a high measure of flexibility, he said, is an indispensable guarantor for such success, particularly with regard to the ongoing extraordinary concentration process in the brick and tile industry as well as in the clay-working engineering sector, in order to keep abreast of constant changes in the market situation. For Händle, this means that it takes constant improvement to achieve “maximum customer satisfaction through excellent quality“. Gerhard Fischer is convinced that, even in a 100 years, the production of both clay-based building ceramics and clay-working machinery will still be branches marked by high value creation. The huge wealth of experience, which, together with innovations, consistently drives the industry forward, is one sure indication of that. Counting off some of the more prominent developments from the house of Händle, he mentioned, for example, the Nova II roof tile press that revolutionized the shaping of oversize roof tiles, and the Wega turntable press for accessory tiles. For material preparation, he cited the Alpha fine roller mill as a highlight of continuous development. With effective roller gaps all the way down to

0.5 mm, it enables ultrafine comminution of plastic and semi-plastic ceramic industrial minerals. Another milestone he mentioned was Händle‘s invention of the extruder simulation model ESM, which helped engineer the new E series of extruders. In that connection, Fischer underscored the importance of Händle‘s continuously optimized and expanded laboratory, where the DasyLab computer system is now in use for further processing all laboratory findings in preparation for transferral from lab scale to production scale. Händle‘s plant engineering work is also being permanently advanced and refined. In the course of a walking tour, Gerhard Fischer noted that, as of January 2015, all plant engineering will be attended to in 3D technology.

Under the motto “Putting together what belongs together“, he illuminated the significance of Händle‘s acquisition of die-maker Braun for the brick and tile industry. For Händle, the die, as the “essential shaping tool in the shaping chain”, is one of the most important elements of an extruder. Now, Händle-Braun customers are getting their systems from a single source that carries all the responsibility. The fact that Braun also has access to the extruder simulation model means that their dies can be further refined and sophisticated through synergistic effects and “concentrated“ competence.

Joint customer care activities are also geared for additional optimization and expansion. To remain successful on the market, Händle is directing additional attention to service and spare/wear-parts activities, where, in order to react even more rapidly, an optimally equipped warehouse and in-house production are considered indispensable.

Factory tour from A(pprentice workshop) to Z(ooming machines)

A subsequent tour of the plant and laboratory provided the guests with an impression of the machine manufacturer‘s high performance.

With its new logistics centre, the company has made itself fit for the future. Between 2011 and 2014, Händle spent approx. € 2.8 million on buildings and infrastructure and, in 2013/2014, invested roughly € 1.2 million in plant and machinery. With floor space totalling 1540 m², the new logistics centre has plenty of room for high-bay racking. Measuring 400 m long by 7.5 m high, the racking installation can hold up to 3474 Euro pallets and a respectable 4600 or so different component parts. So, Händle can react quickly when servicing is required. Fast, flexible, single-item manufacturing with a high real net output ratio pays further tribute to the company‘s guiding principle of maintaining consistently high quality in products and services alike.

At the in-house training workshop the guests encountered a host of budding machinists, steel-construction fitters, industrial mechanics and service technicians, in addition to mechanical engineering students from the Duale Hochschule (cooperative state university), because Händle has been attaching great importance to training ever since 1934 – with more than 900 trainees to date and a workforce apprenticeship quota of approximately 10%. Otherwise, Gerhard Fischer emphasized, as a mid-range enterprise, Händle would not stand a chance in competition with major companies for qualified junior staff.

Then came a genuine “Swabian lunch” with ample opportunity for getting to know each other and talking shop. Finally, a Segway course set up in front of the new logistics centre invited one and all to show off their speed and skill.

Saturday, September 27, was family day, where the company thanked their past and present employees and their families for all their good work over the years, without which Händle would not have become what it is today.

Anett Fischer