Extruded lamination – sometimes a friend, usually a foe of ceramists

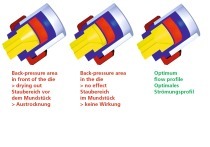

Across the brick and tile industry, the most-used shaping units are continuous extruders, primarily of the de-airing type, but also, if quite rarely, roller presses. These machines‘ basic principle of plastic forming, together with the mineralogical composition of heavy clay bodies, always and unavoidably produces lamination in the extruded column or shaped product.

This paper looks into three essential types of lamination and their causes, optical characteristics and potential effects on the product. Some selected methods of detecting lamination are explained, with distinction being drawn between qualitative and quantitative techniques. In actual practice, the objective is always to minimize lamination by appropriate means with regard to the composition of the working body and to the conditions of preparation and shaping such that, if possible, no lamination-related problems occur during the production process or appear as quality defects on the finished product. How such optimization can be successfully implemented is illustrated by way of several specific examples with regard to roof tiles and clinker bricks.

Dr.-Ing. Rainer Bartusch, KI Keramik-Institut GmbH