Fels-Werke wins German Occupational Health and Safety Award for Innovation

Now, mortar arrives at the site not as a dusty powder but in the form of compact pellets that can be quickly mixed with water and applied without raising a lot of dust.

Dr. Ulf Boenkendorf, Head of R&D, calls attention to another benefit of this innovative product, which is scheduled to hit the market in 2017: “Our compact mortar pellets have a > 20 % higher specific yield than that of conventional, dry mortar.“ For the companies concerned, this means savings in terms of less material expended, lower transport costs and faster on-site work progress. No more tedious, bothersome mixing of thin-layer mortar with big, heavy stirring gear.

Innovative Fels compact mortar pellets make it much easier for construction companies to comply with the new (2014) General Workplace Particulate Exposure Limit.

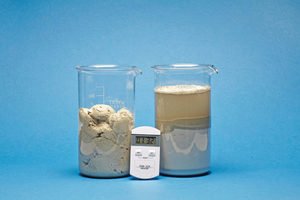

The decisive factors in the pellets‘ production are what is called “agglomeration by compression“ and the pellets‘ large interspatial volume, which promotes an intensive capillary effect upon addition of water at the site. Consequently, the compact mortar lends itself to quick and easy on-site processing: Just pour the pellets into a tub, add water and mix with a trowel. No electric mixer is needed. It takes some minutes to thoroughly mix conventional mortar with an electric mixer and get it ready for use, but it only takes about 90 seconds to turn Fels pellets into ready-to-use thin-layer mortar.