Gas-fired microturbines in the brick and tile industry –

economical and climate-friendly

Gas-fired microturbines (GMTs) have proven effective as cogeneration systems in the clay brick and tile industry. On the road map towards CO2-free production of bricks up to 2050 [1], they can help reach an important milestone. On account of their specific technological features, optimum application areas result especially in the direct utilization of exhaust gas. The current framework conditions of Germany‘s Combined Heat and Power Act 2020 (KWKG 2020) and Renewable Energy Resources Act 2017 (EEG) for in-plant supply of electricity show highly lucrative plant concepts. The long plant operating lifetimes and the cost spread between the energy sources gas and electricity result in short payback times.

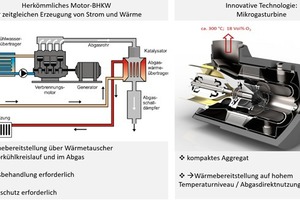

1 Design and operation of gas-fired microturbines

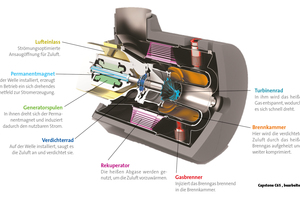

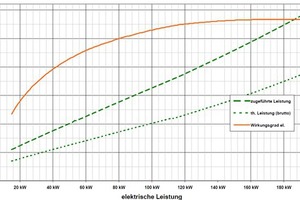

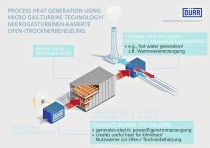

Gas-fired microturbines (GMTs) are compact high-speed gas turbines with electrical power up to around 250 kW. They are single-shaft turbines with a single-stage radial compressor as well as a radial power turbine. The permanent magnet of the generator is also permanently fixed to this shaft (»1). The only moving part of the GMT is the through-shaft with the generator, compressor and turbine wheel. The compressed and consequently preheated air flows through the recuperator and is then fed into the combustion chamber, where it is first mixed with fuel and combusted at temperatures of around 850 °C with high excess air. The hot combustion gases are then relaxed in the turbine, driving the compressor and the generator. The recuperator improves the electrical efficiency. At speeds up to 96 000 rpm, a high-frequency alternating current is generated, rectified in the power electronics device and then transformed into grid-compliant alternating current. The “electronic gearing” enables very fast power regulation from around 10 % to 100 % of the electrical power based on the speed. The temperatures inside the turbine and in the exhaust gas remain relatively constant as a result. For this reason, GMTs exhibit relatively low efficiency losses in partial-load operation (»2).

Key supplier for gas-fired microturbine technology in the power range relevant for the brick and tile industry is the company Capstone. The following remarks refer to applications in which GMTs from this manufacturer are used. The German manufacturer Dürr Systems GmbH closed its GMT division at the end of 2018. The machines boast long service lifetimes of 80 000 operating hours and a low maintenance requirement, which is essentially down to the air bearing. This results in long maintenance intervals of 8 000 operating hours until replacement of air filters becomes necessary, and 48 000 operating hours up to testing of the “powerhead” [2]. Partial and full maintenance contracts are available, which work out much cheaper in comparison with those for motor-powered CHP plants because oil changes are not necessary.

1.1 Conventional and renewable fuels

Capstone GMTs are currently operated with natural gas in the brick and tile industry. The use of renewable fuels, like, for example, biogas, sewer gas or landfill gas is already standard outside the brick and tile industry. It is generally possible to use additions of up to 20 vol% hydrogen and other fuels from power-to-gas plants available in the future.

1.2 Power ranges

According to plant analyses, the brick and tile industry employs a wide spectrum of power ratings and models of gas-fired microturbines (»3).

2 Potential applications as cogeneration plants in the clay brick and tile industry

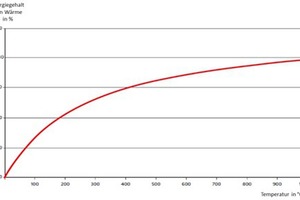

The energy and resource efficiency of a brickworks can be crucially improved if the value of energy is taken into consideration [3]. Energy per se cannot be lost. The high-value part of the energy, the exergy, on the other hand, can be (»5).

Thermal processes, e.g. drying applications in the brick and tile industry at a temperature level to 300 °C should therefore be supplied with waste heat from power generation. The chemically bound high-value exergy part of the natural gas with utilizable combustion temperatures well over 1,000 °C can be used, for example, in a gas-fired microturbine and is not lost. That saves resources.

In the brick and tile industry with its simultaneous continuous demand for electricity and heat, there is considerable cogeneration potential for gas-fired microturbines with direct utilization of exhaust gas. Brickworks have a considerable electricity base load (often up to 300 kW), which is not reduced even on weekends: For this reason, cogeneration units on the basis of gas-fired microturbines are often used exclusively in the lucrative practice of replacing externally supplied and purchased power.

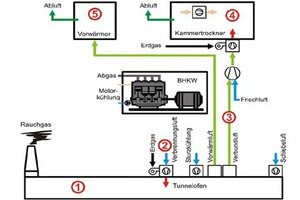

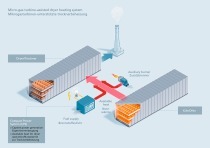

Cogeneration processes must be designed so that the heat produced can be used expediently. Heat sinks in brickworks have been examined intensively [4]. »6 shows the potential applications determined for CHP waste heat. The use of oil-free GMT exhaust gas with around 18-vol% oxygen content and very low concentrations of harmful substances has no adverse impact on the optimized processes of natural-gas-heated heat consumers, like, for example, preheaters and dryers in the brick and tile industry. The exhaust gas characteristics specific to gas-fired microturbines with heat produced continuously on a high temperature level (approx. 300 °C) and the total CHP heat in the exhaust gas stream is a crucial advantage compared to cogeneration units working on the basis of a piston motor (»7).

Possible continuous heat consumers must be determined specific to each brick plant so that reliable data are available for the design of a GMT with long periods of service. In the following, selected application areas are outlined in greater detail.

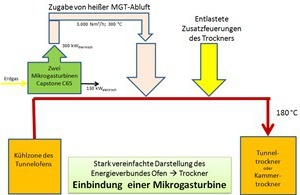

2.1 Integrated tunnel kiln / dryer energy supply network

That declared objective of a thermally independent tunnel kiln on the grounds of fundamental energy-related considerations has not been achieved in existing plants. Optimized tunnel kilns, however, already demonstrate much reduced heat release into the integrated energy supply network. The heat then additionally required for drying is supplied by means of natural gas burners. The direct utilization of GMT exhaust gas reduces the requirement for the natural gas burners (»8 and 9).

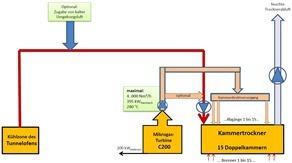

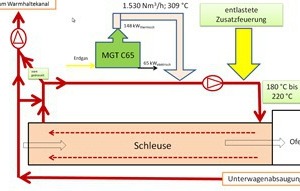

2.2 Heating of kiln entrance air lock

The air lock at a kiln entrance fulfils the function of a preheater and exhibits a heat requirement matching the exhaust heat output by a C65 gas-fired microturbine. The process data do not change. The installed burner with 360 kW rated thermal output remains unchanged.

2.3 Combustion air preheating

Combustion air preheating in tunnel kilns has been propagated as an effective possibility for energy saving for decades [5]. In practice, however, there is a large number of plants in which this has not been realized. If no usable waste heat is available at the facility, the exhaust gas from gas-fired microturbines can be utilized directly. The thermal energy introduced with the combustion air is 100 % usable in the downstream process. Optimum conditions for this type of direct utilization of exhaust gas from a GMT with higher power are offered by combined grinding and drying plants and spray towers (whitewares), as projected facilities show.

2.4 Steam generation

If for plasticizing of clay material, e.g. in a circular screen feeder, steam is needed relatively continuously at a low pressure level of around 3 bar, the hot exhaust gas from the gas-fired microturbine is suitable to make this steam available by means of a heat recovery steam boiler incorporating feed water preheating.

3 Electrical connection

Brickwork sites frequently have their own transformers that are connected to the medium-voltage grid of the grid operator so that VDE-AR-N-4110 code of practice generally applies to the connection and parallel operation of generating plants connected to the medium-voltage grid. GMTs generate electricity on 400 V voltage level, so that the technical requirements of the VDE-AR-N-4105 code additionally apply. Early-stage consultation with the distribution grid operator with regard to concrete requirements in individual cases is therefore highly advisable.

3.1 Feed-in management and balancing energy

For CHP plants over 100 kW electric power, feed-in management is mandatory. Only the feed-in power, that is the power that physically leaves the plant network in the direction of the supply grid, can be regulated [6]. To safeguard the electric grid operation, balancing energy is necessary that can also be supplied by GMT in a brickworks. In the applications presented, the production of heat is redundantly protected. The systems operate continuously under full load and can be run down by remote control as required to serve as negative electric balancing energy. At the same time, the option exists additionally to increase the balancing energy output considerably if the also reduced thermal output from the CHP process is replaced by electrically operated heating registers, e.g. in the integrated kiln-dryer energy supply network.

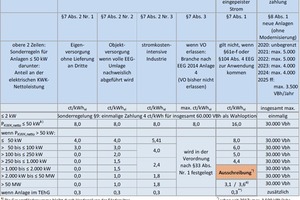

4 Subvention of CHP plants pursuant to Germany’s CHP Act (KWKG) 2020 [7]

On 14.08.2020, CHP Act (KWKG) 2020 came into effect in Germany. The relevant plant sizes below mandatory tendering (from 1 MWelectr.) in the brick and tile industry receive subsidies in accordance with the CHP Act (KWKG) 2020 (»11). Striking is the different treatment of companies’ captive consumption. CHP plants only to an electric power of 100 kW receive subsidies for captive consumption. Privileged are electricity-cost-intensive companies whose captive consumption still qualifies for subsidies even in the case of higher powers. Precondition for subvention is the approval of the plant by Germany’s Federal Office of Economics and Export Control (BAFA) as a highly efficient plant. The AGFW-Worksheet 308 [8] regulates the details. The letter of admission is presented to the grid operator, who is responsible for payment of the CHP subsidies.

For plants up to 50 kWelectr., simplified admission of the CHP plant at the BAFA is possible. For example, a C200 GMT with 200 kW net electric power in an electricity-cost-intensive company that uses the generated power completely internally can justify CHP subsidies of 261 150 euros. If the plant is subject to the greenhouse gas emission trading act TEHG, the subsidy payments increase by 0.3 cent/kWh. Electricity-cost-intensive companies have not realized viable CHP projects in the past because within the framework of the special equalization scheme (BesAR) in accordance with the Renewable Energies Act (EEG), only the externally purchased amount of energy is used to calculate the electricity cost intensity. According to the current regulations on the definition of the electricity consumption and the model for the average electricity prices, this concern is without foundation.

5 Relevant aspects in a GMT feasibility study

The brick and tile industry has to contend with high electricity prices compared with moderate natural gas prices. The spread between the purchase prices is an important indicator for the cost-efficient operation of a CHP plant. With a high base electric load of the site all year round and permanently usable heat sinks, CHP systems in the brick and tile industry are designed such that both the generated electrical energy and the heat can be utilized completely in the plants. The electricity generated in this way is exempt from tax on electricity and the energy tax is reimbursed for the entire natural gas flow rate of the gas-fired microturbine.

The amount of support according to CHP (KWKG) 2020 is designed such that it almost completely hedges the investment in the machine. For regular operation, besides the maintenance costs, other aspects must be taken into consideration: The EEG [9] charges captive electricity consumption proportionally with 40 % of the EEG-levy. In future, the EEG levy is to be capped from government funds. In the year 2021, to 6.5 cent/kWh and in the year 2022 to 6 cent/kWh.

5.1 European CO2 emission trading and national fuel emission trading act (BEHG) [10]

GMTs often form part of the equipment for firing ceramic products requiring licensing, which falls under the scope of application of the German Greenhouse Gas Emission Trading Act (TEHG). Gas turbines per se are only subject to the TEHG only from a rated thermal input of > 20 MW.

In the European emission trading system (EUETS), the prices for CO2 certificates are determined on the market. Before the Corona pandemic, they stood at 25 euros/t CO2. In the year 2021, Germany is launching a national CO2 pricing scheme based on fuel purchase according to the BEHG and is therefore making the price of, for example, purchasing natural gas more expensive. »11 shows the surcharges and the resulting costs for CO2 emitters. The BEHG specifies that for the use of fuels in plants that are already subject to European emission trading (EUETS) there should be no double burden (§ 7 Abs. 5 BEHG). It is not expected that the prices in the EUETS will be above those in the BEHG. In all feasibility studies, therefore, CO2 prices are taken conservatively in consideration of the BEHG. The payback time depends on the achievable operating hours in full-load conditions. Installed plants in the brick and tile industry show for 11 months production time annually, GMT running times of around 8 000 operating hours/a. In the spread between the purchasing costs for the fuels natural gas and electricity and a plant lifetime of 80 000 operating hours, very good economic efficiency results with short payback time.

With the substitution of the electricity purchasing price and utilization of the subsidy payment in accordance with the KWK Act, the most economically favourable operating situation results. The reason is the always lower feed-in remuneration compared with the electricity purchasing price.

6 In-plant power generation by means of gas-fired microturbines – no contradiction to photovoltaics

PV plants and CHP plants are climate-friendly and can usefully complement each other in the brick and tile industry. For economic reasons, in-plant power generation systems should be sized such that the facility’s base load can as far as possible be covered by the CHP plant. The remaining daily load profile forms the basis for a (smaller) PV unit matched to the required power. While a CHP plant with 100 kWelectr. can substitute up to 850 MWh/a purchased electricity, this is not possible with a PV system without an absurdly large storage unit. To generate the same quantity of electricity on the balance sheet, a PV system with around 900 kWPeak would be necessary. For threefold higher investment for the generation of the same amount of electricity per annum, a three-times-longer payback time is required for the PV plant.

7 Impact of the use of an GMT in a brickworks

7.1 Plant safety

Assuming compliance with the regulations on industrial workplace health and safety, the introduction of a GMT operated with natural gas does cause any additional or other hazards. The gas-fired microturbines comply with the safety regulations that apply in Germany. As soon as an unacceptable anomaly occurs in the power grid, the turbine is automatically disconnected from the grid. Option: The plant can be installed as a stand-by power system. The plant would be initially disconnected from the grid and then started up again for the supply of a defined group of consumers with adapted power using a battery pack included in the turbine housing. Occupational health and safety issues with regard to the system noise cannot be expected with the noise levels guaranteed by the system manufacturer. No special measures are needed to protect employees’ hearing.

7.2 Pollution control

Natural gas is burned in a gas-fired microturbine with high excess air (λ = 7 to 8) in a combustion chamber at temperatures from 850 to 900 °C. Emissions of nitrogen oxides, carbon monoxide and hydrocarbons are low. The emissions are well below the emission limits specified in Germany’s Technical Instructions on Air Quality Control (TA-Luft) and the emission requirements of the 44th Federal Emission Protection Act (BImSchV) [11] for gas turbines that require licensing. The manufacturer specifies NOx values < 20 mg/m3 and CO values < 50 mg/m3 (in relation to 15 vol. % O2 in the exhaust gas). Formaldehyde does not form during operation of GMT (< 1 mg/m3) in contrast to gas-fuelled motors. Treatment of the exhaust gas to comply with emission limits is not necessary. The maximum sound emissions are guaranteed at < 66 dB(A) at 10 m distance without additional enclosure by the manufacturer. Especially in the case of interior installation in facilities, problems with sound emissions in the neighbourhood cannot be expected. Low-frequency noise emissions according to DIN 45680, as occur with motor-driven CHPs, are not generated during GMT operation. The GMT is free of lubricants so that special requirements from the use of water-polluting substances do not apply.

7.3 Regulatory status of plants

Brickworks are plants requiring licensing in accordance with the Federal Immission Control Act (Annex 1 of the 4th BImSchV; No. 2.10.1 G E). GMT with natural gas use can be subsumed under No. 1.2.3.2 V of the 4th BImSchV. GMTs per se only require licensing from a rated thermal output of 1 MW so that up to now notification pursuant to § 15 BImSchG to the licensing authority has been deemed sufficient. A licensing process according to § 16 BImSchG is then not necessary when adverse impact caused by the change is obviously low and fulfilment of the requirements from § 6 Paragraph 1 No. 1 BImSchG is ensured.

7.4 Climate protection

The fast effective reduction of greenhouse gas emissions is urgently necessary to achieve the goal contractually agreed under international law in Paris in 2015 to limit the global warming caused by greenhouse gases to well below two degrees in comparison with the preindustrial age. CHP systems contribute considerably to resource and climate protection thanks to better fuel utilization. Primary energy is saved. The electricity generated by the GMT is produced almost without loss providing the heat produced is utilized completely. This electricity must, depending on the electricity mix, no longer be generated elsewhere with considerably higher CO2 load/kWh. There results a significant credit of CO2 equivalents so that the CO2 footprint of the products is improved. Besides the economic aspects of the introduction of a GMT with direct utilization of the exhaust gas, the improved energy and resource efficiency is the main advantage compared to natural gas firing for production of e.g. 200 °C hot drying air.

7.5 ISO 50001 requirements

In-plant electricity generation by means of gas-fired microturbines with direct utilization of the exhaust gas takes into account of the value of the energy chemically bound in the fuel and leads to significant CO2 savings. In recertification in compliance with the ISO standard 50003 requirements, the required improvement of the energy-related power as envisaged in ISO standard 50001 must be provable based on the improved primary energy factors for power consumption [12].

8 Conclusion

In the brick and tile industry, CHP potential is considerable on account of the the year-round power and heat requirement. Gas-fired microturbines generate power while producing heat on constantly high temperature level in only one exhaust gas stream. The air bearing of the turbines supplied by the manufacturer Capstone leads to an exhaust gas that is free of oil residue so that the quality standards for ceramic products are not endangered. Optimum are application areas with dryer, preheaters and on account of the clean exhaust gas with approx. 18 vol% oxygen use as preheated combustion air. Systems installed in the clay brick and tile industry show with technologically simple integration and plant lifetimes of 80 000 operating hours considerable CO2 savings, high returns and payback times of less than three years. An improvement in the energy-related performance pursuant to ISO standard 50001 can be achieved with the use of a gas-fired microturbine.

For the investment decision, a more exact examination of the technological, economic and legal conditions of an individual plant should be performed to provide viable basis.

IZF und FGZ, 2009

ZI 6 2015

Dr. Ing. T. Redemann, Prof. Dr. Ing. E. Specht; ZI 4/2020 Seiten 10 – 19

FUSSNOTEN/VERWEISE:

[1] Vgl. „Roadmap zur CO2-freien Herstellung von Ziegeln bis 2050“; Dr. Ing. T.Redemann, Prof. Dr. Ing. E. Specht; ZI 4/2020 Seiten 10 – 19

[2] Quelle: E-Quad Power Systems GmbH, Herzogenrath; Vollwartungsvertrag beinhaltet den vom Hersteller empfohlenen Tausch des Powerhead

[3] Vgl. „Das Ziegelwerk 4.1 wird hybrid sein“; Prof. Dr.-Ing. Christian Schäffer, ZI 6 2015 Seiten 14-20

[4] Leitfaden zur Integration von BHKW in den Herstellungsprozess grobkeramischer Erzeugnisse“ (Freitag, Deppe, Rauh, Niersmann, Süß) 2012

[5] Vgl. z.B. AiF Forschungsvorhaben 15030 N; „Wärmewirtschaft in der Ziegelindustrie“ Dr. Junge, Dr. Tretau, Essen 2009

[6] Bemerkung des Autors: Die in der parlamentarischen Beratung befindliche EEG-Novelle 2021 (Stand 23.09.2020) könnte Verschärfungen bringen, sodass auf eine redundante Wärmeversorgung weiterhin nicht verzichtet werden sollte.

[7] Gesetz für die Erhaltung, die Modernisierung und den Ausbau der Kraft-Wärme-Kopplung (Kraft-Wärme-Kopplungsgesetz - KWKG) vom 21.12.2015, zuletzt geändert am 08.08.2020 durch das „Kohleausstiegsgesetz“

[8] AGFW-Arbeitsblatt FW 308 Zertifizierung von KWK-Anlagen - Ermittlung des KWK-Stromes - Ausgabe September 2015, Energieeffizienzverband für Wärme, Kälte und KWK e.V.

[9] Gesetz für den Ausbau erneuerbarer Energien (Erneuerbare-Energien-Gesetz – EEG 2017) zuletzt geändert am 08.08.2020 durch das „Kohleausstiegsgesetz“

[10] Gesetz über einen nationalen Zertifikatehandel für Brennstoffemissionen vom 12. Dezember 2019 (Brennstoffemissionshandelsgesetz - BEHG)

[11] Vierundvierzigste Verordnung zur Durchführung des Bundes-Immissionsschutzgesetzes (Verordnung über mittelgroße Feuerungs- Gasturbinen- und Verbrennungsmotoranlagen – 44. BImSchV) Inkrafttreten 20.06.2019

[12] Erfahrungen bei der Re-Zertifizierung nach den Anforderungen der ISO 50001 in Verbindung mit ISO 50003; Dr.-Ing. Volker Albrecht, ZI 2/2019 S. 14-25