Modelling shrinkage-related deformation

during the drying of green bricks

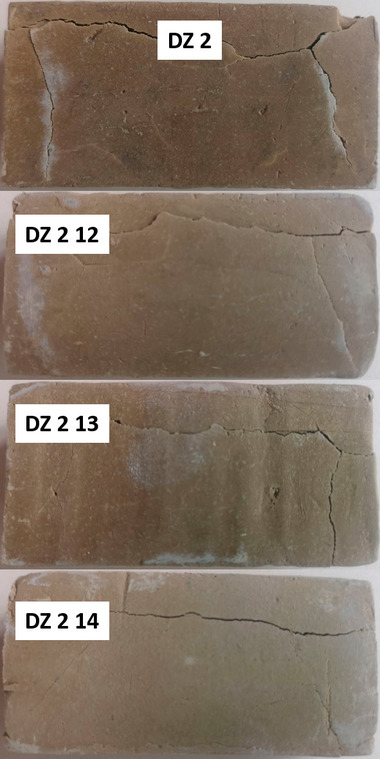

During drying-related shrinkage of green products, non-linear changes in the body geometry occur. These are not caused by an isotropic shortening of length, but shrinkage progressing from the drying surfaces inwards. This leads to movements in the green products, undesirable permanent geometric distortions or cracks.

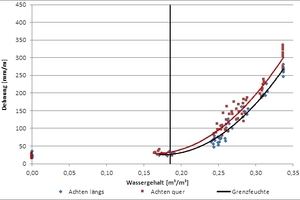

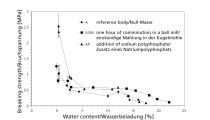

Besides the tensile strength, the plastic behaviour also plays a crucial role with regard to deformability and crack development. With very high moisture content, the plastic deformability is so high that differences in shrinkage are compensated for by changes in shape (warping). With somewhat lower moisture content, the plasticity decreases sharply so that green products become brittle and particularly sensitive to cracks. With further decrease in water, the clay particles move closer together so that with thanks to their adhesion with each other, higher tensile forces can again be withstood. Differences in shrinkage are elastically compensated for to an increasing extent.

Dr.-Ing. Anne Tretau, Institut für Ziegelforschung Essen e.V.