New concept for improving heat transfer

in tunnel kilns

Ceramic products have to be fired before they can be used, and tunnel kilns are well-suited for the job.

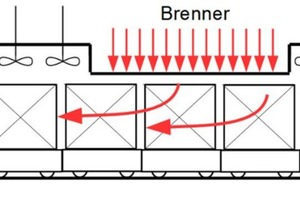

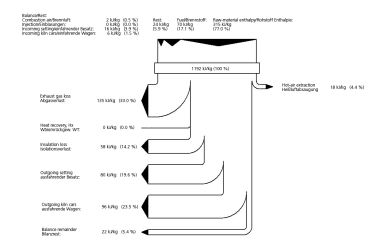

To help optimize a kiln‘s energy efficiency, fans can be installed in the preheating and cooling zones, where they help improve heat transition and temperature homogeneity. Radial impellers like those used for heating aluminium billets to high temperatures are placed directly in the firing channel. This fan-use concept is pursued in several stages. First, at the Brick and Tile Research Institute (IZF), an experimental tunnel kiln is equipped with a hot gas fan to enable simulation of the flow situation within the channel. In parallel, at the RWTH Department for Industrial Furnaces and Heat Engineering in Aachen, CFD simulation of the fan and the conditions of flow within the firing channel is carried out and validated on the basis of the results obtained for the test kiln. Finally, the experimental findings and the results of CFD simulation are fed into the mathematical model of a tunnel kiln that was developed at the Department of Thermodynamics and Combustion at Otto-von-Guericke University Magdeburg.

The concept itself and the initial results of investigation are presented.

M.Sc. Tino Redemann, Otto-von-Guericke-University

Magdeburg; Jan Hof, RWTH Aachen