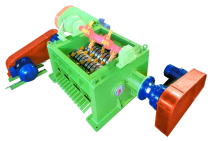

New die for stiff extrusion

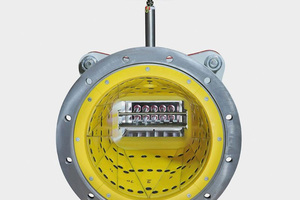

The ground-breaking extrusion system is organized in two different but fully integrated sections: pressure head and die. The most important innovation is the material used, which has been specifically developed to facilitate the sliding and flow of the clay, without neglecting wear resistance. The pressure head is lined with a special coating made of self-lubricating polyamide that is easily and quickly interchangeable, the aim of which is to reduce the extrusion friction. The die is equipped with cores and frame made of alumina characterized by high resistance to wear, while presenting at the same time a clean and smooth surface.

It is important to highlight that together with the equipment of the die section, there is the usual and traditional configuration for external lubrication. The core-holding bridge is manufactured in a CNC machining process without welding, but using wear-resistant materials further protected by a double layer of chromium plating.

The system is enhanced by a digital plastometer in the pressure head, specifically designed to measure pressure and temperature and equipped with PC output.

Bongioanni Macchine S.p.A.

www.bongioanni.com