Optimizing your extruder for better operational metrics

Long-standing partnership, publications in specialized media, word of mouth and in-house proficiency training all promote partner-to-partner dialogue – in which expressed wishes, discussions and the sharing of news, views and experience in turn lead straight to target objectives.

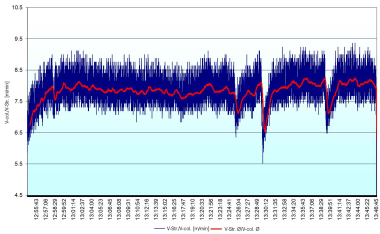

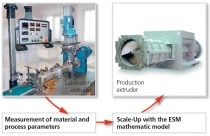

Extruder efficiency can be calculated from a mix of product data (formats), production parameters and the screw press‘ geometrical data. The results can then serve as a decision-making aid for the further course of action.

If the efficiency is already at an appropriately high level, all is well. Usually, though, that is not the case. On average, the typical extrusion system can be expected to be running at some 30 % to 35 % efficiency.

The experience gained on more than 400 examined extruders is invaluable for assessing the performance capacity of the auger. Sometimes, locally recorded data show that the efficiency could be increased from, say, 25 % to 30 % or even 35 % merely by adjusting the current operating parameters to fit products that have been changing little by little over the years.

Once the system‘s efficiency has been dealt with in theory, the practical implementation can begin. Finally, an analysis of results based on comparison of the operating data before and after adjustment of the system‘s geometry usually shows a tweaked efficiency level of some 60 % to 65 %. The new production parameters not only reduce the system‘s energy consumption, but also lengthen the service life of the auger system.

Thomas Kloft, Petersen Service GmbH, Nephen;

Jörg Roters, Rehart GmbH, Ehingen